The rapid growth of population and the trend of urbanization are expected to promote and promote the development and growth of the vertical farm industry. Vertical farms are thought to solve some of the problems of food production, but whether it can be a sustainable solution for food production, experts believe that there are still challenges. According to a UN survey, the global population will grow from the current 7.3 billion people to 8.5 billion in 2030 and 9.7 billion in 2050. FAO estimates that in order to meet and feed the population of 2050, food production will increase by 70% from 2007 levels, global cereal production must increase from 2.1 billion tons to 3 billion tons by 2050, and meat needs to be doubled to 470 million tons.

According to a UN survey, the global population will grow from the current 7.3 billion people to 8.5 billion in 2030 and 9.7 billion in 2050. FAO estimates that in order to meet and feed the population of 2050, food production will increase by 70% from 2007 levels, global cereal production must increase from 2.1 billion tons to 3 billion tons by 2050, and meat needs to be doubled to 470 million tons.

How to solve the problem of demand due to the increase in population? Many people point out that adjusting and adding more land as agricultural production is not always possible in some countries. For example, the United Kingdom has used 72% of the land to produce the most agricultural products, but still needs to import food. The United Kingdom has also tried to use other methods for farming, such as the use of air defense tunnels left over from World War II combined with full-spectrum LED grow lights for greenhouse cultivation. The sponsors also plan to expand the planting range in 2019.《Does The Full Spectrum Grow Lights Cause Harm To Humans?》

《Is The LED Grow Lights Really Useful?》

《Can Be Eaten The Vegetables Which Grows With The LED Grow Lights》On the other hand, water use is also a barrier to food production. About 70% of OECD's water use is for farms. Climate change has also exacerbated production problems. Urbanization also requires food production systems to feed the population of urban populations with less labor, limited land and water resources in the countryside. These issues are driving the development of vertical farms and high-quality plant lights. The low-use nature of vertical farms will provide opportunities for agricultural production to enter the city, closer to urban consumers, reduce the distance from farms to consumers, and shorten the entire supply chain. Urban consumers will be more interested in Food sources and easier access to fresh nutritious production. In the past, urban people did not have easy access to healthy fresh food. Vertical farms could be built directly in the kitchen or in their backyard, using the light provided by LED growing lights, which would be the most important message conveyed by vertical farm development.

The low-use nature of vertical farms will provide opportunities for agricultural production to enter the city, closer to urban consumers, reduce the distance from farms to consumers, and shorten the entire supply chain. Urban consumers will be more interested in Food sources and easier access to fresh nutritious production. In the past, urban people did not have easy access to healthy fresh food. Vertical farms could be built directly in the kitchen or in their backyard, using the light provided by LED growing lights, which would be the most important message conveyed by vertical farm development.

In addition, the adoption of a vertical farm model will have a wide-ranging impact on traditional agricultural supply chains, and the use of traditional agricultural drugs such as synthetic fertilizers, pesticides, and herbicides will be significantly reduced. On the other hand, the demand for HVAC systems and control systems will increase to maintain optimal conditions for climate river management, special LED lighting for simulating sunlight, and other equipment to set up indoors or Outdoor architecture.

For vertical farm development, the Internet of Things (IoT) technology will also play an important role in recording plant growth data, crop harvesting will be traceable, and monitored elsewhere by computer or mobile phone.

In fact, vertical farms can produce more food with less land and water, and away from harmful chemical fertilizers and pesticides. However, shelves stacked indoors require more energy than traditional agriculture. Even if there are windows in the room, artificial light is usually required for other restrictions. Climate control systems provide the best growth environment, but they are also quite energy intensive.

According to the statistics of the British Ministry of Agriculture, lettuce is grown in the greenhouse, and it is estimated that about 250 kWh (kWh) of energy per square meter of planting area per year. According to the relevant collaborative research of the German DLR Research Center, the vertical farms in the same size planting area require an amazing energy consumption of 3,500 kWh per year. Therefore, how to improve acceptable energy use will be an important issue for the future development of vertical farm technology.

However, we believe that with the continuous upgrading of technology, the development of vertical farms will gradually meet the human needs for food, and the development of LED plant lights will also allow agricultural production to enter the city so that humans can enjoy greener foods that are healthier and more environmentally friendly.《How To Build A Successful Plant Factory?》

《The Analysis of Vertical Farm Development Prospect》

It is a very common phenomenon that LED lights are easily darkened after use. Summarizing the reasons for the darkening of LED lights is nothing more than the following three points.

Drive Damage

LED lamp beads are required to work at DC low voltage (below 20V), but our usual mains supply is AC high voltage (AC 220V). To turn the mains into the electricity needed for the lamp, you need a device called "LED constant current drive power."

In fact, as long as the parameters of the driver match the lamp bead, the power supply can be continuously used and used normally. The internals of the drive is complicated, and any device (such as capacitors, rectifiers, etc.) may cause a change in the output voltage, which may cause the lamp to become dark. Drive damage is one of the most common faults in LED luminaires and can usually be resolved after replacing the drive.

Drive damage is one of the most common faults in LED luminaires and can usually be resolved after replacing the drive.

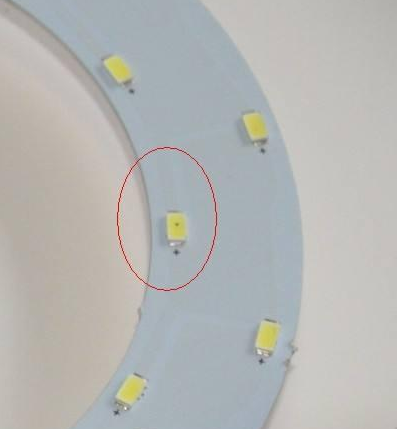

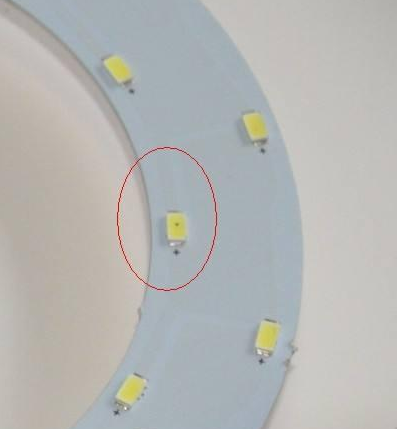

LED Lamp Bead Burned

The LED itself is composed of one lamp bead. If one or a part of it is not lit, it will inevitably make the whole fixture dark. Lamp beads are generally connected in series and then in parallel - so if a lamp bead burns, it may cause a batch of lamp beads to be off.

After burning, the surface of the lamp bead has obvious black spots. Find it, use a wire to connect it to the back of the lamp, short-circuit it, or replace it with a new lamp bead. It’s a coincidence that the LED burns one at a time. If it burns frequently, consider the drive problem - another manifestation of drive failure is burning the lamp bead.

It’s a coincidence that the LED burns one at a time. If it burns frequently, consider the drive problem - another manifestation of drive failure is burning the lamp bead.

LED Light Decay

The so-called light decay is that the brightness of the illuminant is getting lower and lower - this situation is more obvious on incandescent and fluorescent lamps.

LED lights cannot avoid light decay, but its light decay rate is relatively slow, it is difficult to see changes with the naked eye. However, it does not rule out inferior LEDs, or inferior light beads, or due to objective factors such as poor heat dissipation, resulting in faster-LED light decay.

Therefore, when we choose the LED light, we must choose the quality and quality assurance business to ensure that the LED lamp has a longer service life.《5 Ways To Maintain LED Lights》

《How To Choose A High Quality LED Corn Lights》

《How To Choose A High Quality LED Bulb Lights》

Plant Factory And Its Social Significance Plant Factory, in a broad sense, refers to a system of plant cultivation systems that fully or partially controls the environmental conditions required for plant growth to grow completely or partially unaffected by the natural environment. Its main feature is that the planting space is closed, and the artificial light completely replaces the sunlight. The production factors (carbon dioxide, oxygen, temperature, humidity, fertilizer nutrients, illumination, etc.) are fully and accurately controlled. The whole year is continuously cultivated, and the production cycle is fast. Customized by a plan, etc. The whole process is carried out on the factory production line, which makes the product more refined, homogenized and productive.

Plant Factory, in a broad sense, refers to a system of plant cultivation systems that fully or partially controls the environmental conditions required for plant growth to grow completely or partially unaffected by the natural environment. Its main feature is that the planting space is closed, and the artificial light completely replaces the sunlight. The production factors (carbon dioxide, oxygen, temperature, humidity, fertilizer nutrients, illumination, etc.) are fully and accurately controlled. The whole year is continuously cultivated, and the production cycle is fast. Customized by a plan, etc. The whole process is carried out on the factory production line, which makes the product more refined, homogenized and productive.

According to statistics, the global population will exceed 9 billion by 2050. The global issues of the 21st century are four aspects of food, resources, environment, and quality of life. Deterioration of the natural environment includes soil compaction caused by human factors, soil salinization, heavy metal pollution, severe haze, and desertification. Plant factories can solve the supply of vegetables in extreme environments. For example, soldiers working in desert conditions, workers working on offshore platforms need to regularly distribute vegetables and other foods, and only vegetables that are resistant to storage, less Fresh leafy vegetables. In addition, the world's major powers are scrambling to study various technical means of exploring space. Plant factories are an important research topic.

Plant factories can solve the supply of vegetables in extreme environments. For example, soldiers working in desert conditions, workers working on offshore platforms need to regularly distribute vegetables and other foods, and only vegetables that are resistant to storage, less Fresh leafy vegetables. In addition, the world's major powers are scrambling to study various technical means of exploring space. Plant factories are an important research topic.

The Development Direction of The Combination of Plant Factories And Lighting Industry

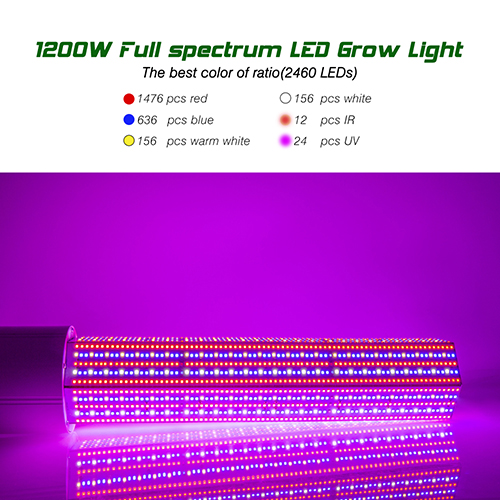

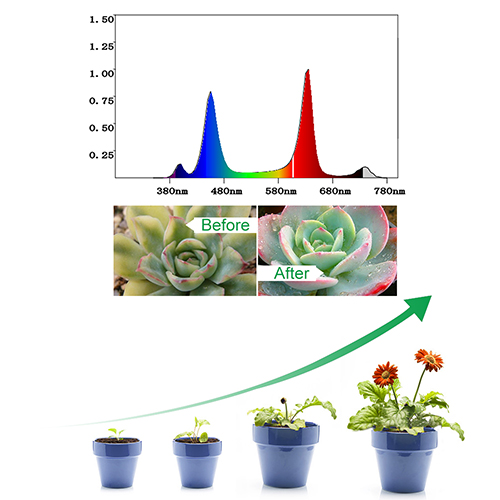

The light sources used in the development of plant factories mainly include high-pressure sodium lamps, fluorescent lamps, metal halide lamps, incandescent lamps, etc. The outstanding disadvantages of these light sources are high energy consumption, high operating costs, and energy consumption costs accounting for 50% of the total operating costs. -60%. In recent years, the LED light source developed not only emits monochromatic light with narrow light waves, but also can arbitrarily combine light sources according to plant needs, and the LED is a cold light source with low heat generation characteristics, which can illuminate plants at close range and improve space utilization. Providing a reasonable light environment for plant growth, it is very suitable for the cultivation of plant plants in multiple layers.

Analysis of The Needs And Ppplication Characteristics of Plant Lighting Equipment in Plant Factories:

The basic requirements for the application of LED light source in plant factories are mainly reflected in three aspects, namely spectral performance - both to ensure the photosynthetic quality of plant photosynthesis, and to reduce the invalid spectrum and energy consumption as much as possible; luminous efficiency-- The amount of photosynthetically active radiation emitted is relatively high compared to the power consumption; the service life - long use time, low light decay, and relatively low price.

There are three main factors affecting the growth of crops grown in plant factories by LED light sources:

1.Light intensity - the intensity of light. It will not only affect the photosynthesis intensity but also change the shape of the crop, such as flowering stage, internode length, stem thickness, and leaf size thickness;

2.The photo-spectral distribution has an important influence on plant photosynthesis and morphogenesis. The plants on the earth are constantly adapting to solar radiation during long-term evolution, and different species have different light-selective absorption characteristics.

3.Photoperiod-photoperiod characteristics are closely related to the number of illumination hours. Different crops need a certain number of illumination hours to complete the photoperiod, and the opposite can also inhibit the flowering and fruiting of the crop by changing the illumination time.

The impact of a LED light source on the construction and use cost of plant factory. At present, the cost of the LED light source in plant construction accounts for 20%-50% of the construction cost, and the compression space is large; the installation efficiency, maintenance replacement frequency, power saving ratio, Attenuation speed, etc. will affect the actual use cost.

Future Development of Plants Combined With Plant Lighting Technology:

The cost performance of LED has been significantly improved in the past few years. Therefore, the industry of LED-based artificial light-type plant factories has also developed rapidly in recent years. It can be convinced and predicted that LEDs are based on LEDs with increasing cost performance. The artificial light plant factory will have a broader development space. The rapid rise of plant factories has also prompted the plant lighting industry to move forward in a favorable direction of research and development, standardization, and close cooperation between industries. In order to promote the efficient and healthy development of LED artificial light plant factories, the following problems need to be solved:

In order to promote the efficient and healthy development of LED artificial light plant factories, the following problems need to be solved:

1.In-depth study of the effects of artificial light sources on plant growth in plant factories. The complexity of plant photobiology research has made the mechanism of photobiology unclear so far, especially in the field of molecular biology. First of all, there are many kinds of plants and varieties, and photobiological needs are very complicated. Secondly, the wavelength of plant effect light is complex, involving many typical bands, and the individual effects and complex effects require long-term research. Finally, the most complicated is plant development. The output and quality indicators are diverse, the light control is difficult, and the single-index and composite indicators are complex. This requires close cooperation between the two industries to promote the solution.

2.Formulation and implementation of relevant standards for lighting fixtures for plant factories. Compared with lighting fixtures for homes, shopping malls, etc., LED agricultural use, especially for plant-specific lighting fixtures, still has product clutter, irregular production design, lack of uniform product standards and quality management issues. In addition to the lack of scientific uniform specifications in terms of light quality regulation and light intensity, there is a lack of design specifications for protection against electricity, water, and corrosion in high-humidity environments of plant factories. Some lamps have a short service life and potential safety hazards.

3.The improvement of technology research and development investment and intellectual property protection system. At present, there are many small and medium-sized enterprises producing low-end products in LED plant lighting fixtures, lacking independent intellectual property rights and systematic research, which makes LED plant lighting products uneven, industrialization and standardization are low, and lack of market competitiveness.

High-end facility agriculture is the development trend of modern agricultural planting, and plant factories are the typical representative of this new concept and technical system. It can realize the high-efficiency agricultural system for continuous crop production through high-precision environmental control in the facility. It is the automatic control of the environmental conditions of plant growth by using a computer. It is a subversion of traditional agriculture, making plants grow free or rarely subject to natural conditions. The labor-saving production mode that is restricted is the advanced stage of agricultural development.

In the next three to five years, more industrial resources will enter, more capital will enter, and with the introduction of government support policies, the development of plant factories will enter a period of vigorous development. The development of plant factories has benefited from the good early stage of the LED industry, and the LED plant lighting or agricultural lighting field that has been or has been deployed by various LED companies. It is foreseeable that the cost of plant lighting is reduced and the professionalism is improved. As well as the continuous professional development and strategic cooperation of other related upstream industries, the plant factory will flourish, benefiting the general trend of consumption upgrading, and can solve part of the shortage of energy and cultivated land.XinJia is also constantly striving and innovating to provide customers with more high-quality LED grow lights.

Want to know more about plant factories?Browse the following articles:《How To Build A Succuessful Plant Factory?》

《LED Plant Factory-A New Dirextion For The Development of Smart Agriculture》

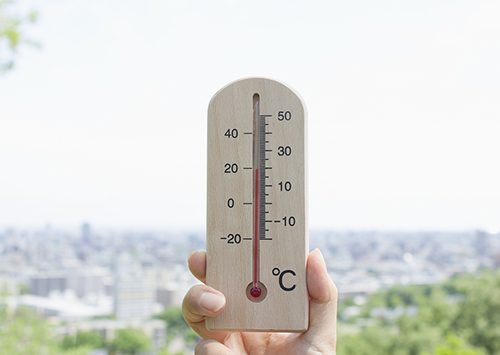

With the promotion of the legalization of marijuana, more and more people choose to buy seeds and LED grow lights to grow marijuana. As we all know, the cultivation of cannabis is not as simple as we think: temperature, climate, soil, water seal, light and other factors are essential for the growth of cannabis.

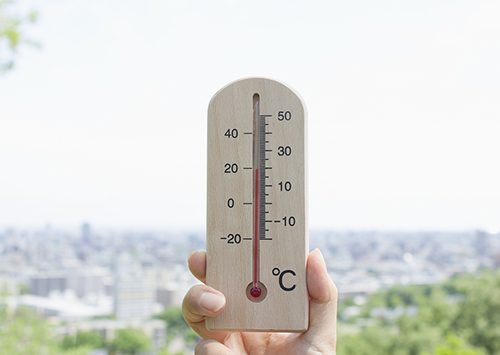

In fact, cannabis has different temperature requirements depending on the type of variety. Generally, from planting to maturity, the accumulated temperature required is 1900-2000. When the seeds are mature, the accumulated temperature is 2700-3000. For early maturing varieties, the accumulated temperature of 1600-1700. The process can be matured. Cannabis seeds can germinate when the soil temperature is above 1 °C, but it is necessary to sow when the soil temperature is above 8-10 °C. The optimum temperature for cannabis seed germination is 25-35 ° C. When the temperature is high, the germination is fast and uniform, and the highest temperature is not more than 45 ° C. Excessive temperature is easy to burn the seeds. Cannabis seedlings can withstand short-term low temperatures of -5 ° C, but this can seriously affect their growth process. The most suitable growth temperature: seedling stage is 10-15 °C; rapid growth period is 18-30 °C, 19-25 °C is the most suitable; flowering to seed maturity is 18-20 °C, flowering period meets -1 °C low temperature, then The flower is damaged, and the flower is dead below -2 °C, especially the male flower.

Cannabis seedlings can withstand short-term low temperatures of -5 ° C, but this can seriously affect their growth process. The most suitable growth temperature: seedling stage is 10-15 °C; rapid growth period is 18-30 °C, 19-25 °C is the most suitable; flowering to seed maturity is 18-20 °C, flowering period meets -1 °C low temperature, then The flower is damaged, and the flower is dead below -2 °C, especially the male flower.

Seeds can withstand 3-5 ° C low temperature and lower temperature within 10-15 days after germination; at -5 low temperature, its growth will be delayed. However, if sufficient water and nutrients are available, the low temperature at the seedling stage will have little effect on future development and yield.

Cannabis is not resistant to low temperatures during flowering, and it is prone to death during the flowering period, and it is easy to die. During the growth period, the average temperature around day and night has a great influence on the growth of cannabis, especially from the bud to the end of flowering, the growth of stems is the fastest, and the dry matter is greatly increased; during this period, the best temperature should be maintained at 16 (evening)-25 °C (daytime) or so. With the use of LED plant lights, indoor cannabis cultivation can better control the temperature required for cannabis by hand. Regardless of the planting method, we should be careful and caring for the cannabis in planting.

With the use of LED plant lights, indoor cannabis cultivation can better control the temperature required for cannabis by hand. Regardless of the planting method, we should be careful and caring for the cannabis in planting.

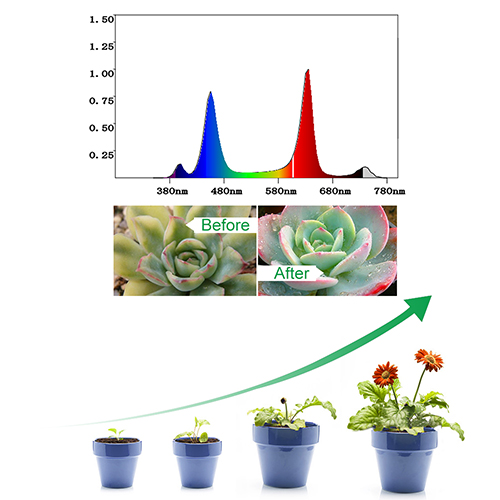

In the spring, changing pots, breeding, and fleshy growing up in spring is the season for all things to grow. For those who love fleshy, this is a season where you can buy more meat, more flesh, and more flesh. Although the spring climate is suitable for fleshy growth, it is also a good time to change pots and breed. However, succulent planting in spring will also encounter some problems, avoiding the following problems and making succulents grow better in spring.

1. Why Is My Succulent Sunburned In The Spring?

Many fleshy people who spend winter indoors, long-term exposure is the weaker sunshine, and the sunshine time is relatively short. Suddenly accepting unobstructed glare is very easy to sunburn. This is because fleshy cannot adapt to the sudden change of the environment, so in the winter when the sun is insufficient, we can use the LED grow lights to help the plants provide some light, and when the outdoor cultivation begins in the spring, we should pay attention to gradually increase the sunshine duration.《Is The LED Grow Lights Really Useful?》

《Why We Need LED Grow Lights?》

2. When Can Succulents Move From Indoors To Outdoors?

The succulent plants need to be moved into most areas of the winter for indoors, and the minimum temperature will rise above 0 °C until around the beginning of March. The temperature varies slightly from place to place. It can be judged according to the weather forecast. When the minimum temperature is stable above 5 °C, it can be moved to outdoor maintenance.

3. There Are Too Many Fleshy Roots. How Do You Get on The Basin?

First, clean up too much root system and put it in a cool, ventilated place to dry the wound. Put about half of the soil in the pot, then spread the dried fleshy roots evenly, and then continue to add the soil.

4. What Should I Do If I Can't Remove The Flesh When I Change The Basin?

When changing the succulent plants, sometimes the roots and soils are too tight, and the succulents cannot be removed smoothly. At this time, it is forbidden to remove the succulent plants with brute force, otherwise, it is easy to damage the root system. If it is a plastic flower pot, you can squeeze the pot wall hard, separate the soil from the flower pot, and then pour out the succulent plants. If it is a pottery basin, a metal basin, a glass basin, etc., it can be tapped with a rubber hammer. After the pot is loose, remove the succulent plants. You can also loosen the potting soil with a small tool and then remove the flesh. 5. How Do The Succulent Plants That Are “Cut Down”Take Root?

5. How Do The Succulent Plants That Are “Cut Down”Take Root?

The cut meat will be dried in turn, and most of the succulents will dry for two or three days. Prepare slightly moist sand and place the "head" on the sand. Waiting for the roots of the flesh only need to keep the soil moist, you can not water.

6. To What Extent Should The Roots Be Repaired?

Rooting is a necessary step in the past. The practice has proved that the meat after the roots is better than the uncooked meat. But to what extent the refinement has to be repaired, many people are not very clear. In general, roots with fewer roots do not need to be rooted, and the black roots, dry roots, and most of the roots are preserved, leaving only the main roots. The roots of the fleshy old piles need to be taken care of to cut off the severely rooted roots. 8. Want To Insert The Leaves, How To Lick The Leaves?

8. Want To Insert The Leaves, How To Lick The Leaves?

The leaves of rainbow jade, peach beauty, peach egg, etc. are relatively thick, and the varieties with few leaf growth points and stalk joints are relatively easy to lick the leaves and can be removed by gently twisting left and right. For ruby, blue stone lotus, hibiscus snow lotus, etc., or the blade itself is too brittle, or the leaf growth point is more connected with the stem, or the leaves are denser, it is best to change the basin, beheaded or occur when the length is longer. The blade is so as to ensure the integrity of the blade growth point. If the leaves of normal plants are picked, they should be picked when the pots are dry. If the leaves are dense, you can use the tweezers to gently clamp the leaves (as close as possible to the base), and see the left and right movements, feel the degree of separation of the growth points and stems, and slowly apply force. The intensity is very important. Through long-term practice, you will slowly find you.

9. What Should I Do If The Leaf Growth Stage Is Slow?

One reason for the slow growth of leaf seedlings may be that there is a problem with the root system. It can be replanted once, allowing the roots to re-emerge and grab the soil. It may also be a problem with the soil. The roots of the seedlings are fine and soft, and it is not easy to take root in the harder soil. Therefore, the cultivation of seedlings should be based on the peat soil charcoal, which is loose and retains water. In addition, the seedlings have few roots, and the water absorption capacity is not as strong as that of the plants, so it is necessary to spray frequently. Don't be afraid of water, the new root of the seedlings is very fond of water, as long as the basin does not contain water. 10. After The Leaves Are Inserted Into The Buds, The Dried Mother Leaves Are Picked Or Not Picked?

10. After The Leaves Are Inserted Into The Buds, The Dried Mother Leaves Are Picked Or Not Picked?

The mother leaves may be dried for various reasons shortly after the leaves are inserted, and the mother leaves can be removed at this time. If it is mother leaf water or mold, it should be removed immediately to avoid transmission to seedlings. If the mother leaves are slightly wrinkled during the curing process, they should be watered immediately. Long-term water shortage can easily lead to dryness of the mother leaves. The well-preserved leaves are inserted into the seedlings, and the mother leaves will always be healthy. When the seedlings grow long enough, the mother leaves can be removed and the leaves inserted again.

11. What Should I Do If The Leaf Inserts Only Grow Long?

The time when the leaves are inserted into the roots is not consistent. Some will first sprout out and then sprout. Usually, don't worry about this situation. If you sunbathe the sun properly and spray the water to keep the soil moist for a few days or 1 week, small shoots will grow. If there are no small buds growing out after several months, try to cut off the original roots and let the leaves re-root.《How TO Grow The Succulents?》Do you have more experience with the growth of succulents? Feel free to share your experience in growing succulents in the comments~

A few days ago, many reports announced that two French vegetable growers have installed 1000W LED plant lighting in their greenhouses to help grow cucumbers throughout the year.

According to the news, both growers installed LED plant lights in their new cucumber greenhouse (located in the Nantes region of France). The two are the first growers in France to use LED lamps to grow steel cucumbers, demonstrating their leadership as a member of the grower cooperative. Experts point out that LED lighting can help increase crop yields, and because LEDs don't generate too much heat as the light increases, LED lighting also allows growers to control light and temperature more precisely. These features ensure the high-quality production of the crop throughout the year as efficiently as possible.

Experts point out that LED lighting can help increase crop yields, and because LEDs don't generate too much heat as the light increases, LED lighting also allows growers to control light and temperature more precisely. These features ensure the high-quality production of the crop throughout the year as efficiently as possible.

In fact, LED lamps to provide better heat and light balance. Compared to high-pressure sodium lamps, LED lamps can greatly increase production without generating heat. According to calculations, the 20,000-square-meter semi-enclosed greenhouse is illuminated by LED lights, and the output will be 30% higher than the output of traditional greenhouses without LED lights.《Four Major Trend of LED Lighting In 2019》

《New Trends In Plant Lighting,Corporate Development Attracts Attention》LED lighting will help companies improve energy efficiency and reduce production gaps, especially in the winter when revenues are greater. This plays a key role in maintaining the company's position in the market throughout the year. At the same time, it has alleviated a problem of shortage of vegetables on the market. Undoubtedly, LED plant lights are constantly changing our lives.

In the field of plant lighting, as one of the fastest growing agricultural lighting fields in recent years, LED has obvious advantages in plant lighting because of its high luminous efficiency, low heat generation, small size, and long life. Plant lighting and other LED lighting With the maturity of the technology, companies have moved from the general lighting market to the field of plant lighting, and plant lighting has broad prospects.

So, what problems exist in LED plant lighting in the process of development? What is the current proportion of LEDs in plant lighting? What is the future trend of LED plant lighting compared with other light sources in plant lighting?

1. How To Treat The Current Development of The Entire LED Grow Lighting Industry?

The future development prospects of the plant lighting industry are very optimistic. From the current sales volume of plant products, whether it is the starting leaf or the health food, or even the medicine that will become the future trend, whether at home or abroad, these products The price of the plant is getting higher and higher, and the future of plant lighting must have a bright future.

The premise is that your product must be distinctive. For example, marijuana, with a high added value of products, and products with characteristics, the next step to determine whether the industry is successful is to see who can successfully implement the commercial marketing model. The life cycle of plant products is very short, but many people will not sell them, and the products will not be sold. In fact, products need different routes. From fresh vegetables to processed products, from semi-finished products to finished products, when products become diversified, the channels of sales become diversified. Sales naturally go up. 2. At Present, LED Accounts For The Total Market Share Of Plant Lighting Fixtures?

2. At Present, LED Accounts For The Total Market Share Of Plant Lighting Fixtures?

At present, the plant lighting lamps used in greenhouses are mainly high-pressure sodium lamps. The LED lamps are practically few. In recent years, the application growth rate in the cannabis field has accelerated. Some plant factories also use LEDs, but in general, LEDs currently account for a small percentage.

3. What Are The Advantages of Vegetables Grown With Plant Lighting Compared To Ordinary Vegetables?

The first biggest feature is that the vegetables grown in the plant factory are very safe. Only in a controlled environment, it is illuminated with LED lights. By artificially controlling its environment and nutrient solution, it is beyond the green vegetables, and There is no need to use any pesticides or herbicides in the plant, and our nutrient solution avoids the contamination of heavy metals in traditional soils.

The second feature is that because of the artificially created shortcut environment, the air is filtered, the water is purified, and the dust and bacteria content is very low. The third characteristic is that the products of the plant factory are very fresh. Compared with the losses caused by long-distance transportation of other traditional agricultural plants, the plant factory is placed around the big city. It can be completed within 12 hours from the receipt of the table, and the effect of planting vegetables at the door of the house. it's the same.

The third characteristic is that the products of the plant factory are very fresh. Compared with the losses caused by long-distance transportation of other traditional agricultural plants, the plant factory is placed around the big city. It can be completed within 12 hours from the receipt of the table, and the effect of planting vegetables at the door of the house. it's the same.

In addition, compared with traditional agriculture, plant lighting factories can be customized. Traditional agriculture is limited by the fact that climate and temperature change all year round. Although greenhouse greenhouses can now eat anti-season products, plant factories have no concept of season. The products are the same throughout the year and are highly efficient.《The Fill Light Method And Development Direction of Plant Factory》

《LED Plant Factory-A New Direction For The Development Of Smart Agriculture》

《The Analysis of Vertical Farm Development Prospect》

4. Are There Any Defects In The Vegetables Grown At The Plant Factory? Will Artificial Planting Change The Structure Of The Dish, oOr Is There An Unknown Problem Such As Genetic Modification?

Artificial light is basically the same as sunlight, and there is no difference in the growth of plants. The only difference is that if the plant is reddish, you will use the exact spectrum, it will produce lettuce with the normal coloration of red leaves, but you said that the lack of anthocyanins in vegetables will be different, but fewer nutrients. The dishes that may be planted by the hydroponic system will be tenderer, some people like it, and some people say it is unnatural. Plant factories use data to speak. We adjust the light to produce a beneficial component. The ratio of blue light to red light in the sun is fixed, but the lighting can make more of the ingredients we need, but it does not change the vegetables. Genes, this is the ability of the plant itself, we have not changed the genes of plants.

Nutritional ingredients are the end use of vegetables. Some nutritional values are higher. Some nutrients are not what we need. When we need a certain component of plants, we can regulate them through physical conditions. This is the benefit of plant factories. The growth of beneficial components of the human body, or by changing the growth environment of the vegetables to adjust different tastes.

5. How Do You Think About The Development Of Cannabis Cultivation?

Cannabis itself is a double-edged sword, and its medication value is beyond doubt. There are different laws in different states of the United States, depending on how the local government views it. Many states in the United States have legalized the cannabis market, and mature lamps are now in use. Moreover, they are now looking for a more efficient LED luminaire solution than the high-pressure sodium lamp. If your LED luminaire solution has no obvious advantage over the high-pressure sodium lamp currently used, there will be some obstacles in the promotion. 6. What Are The Advantages And Disadvantages Of LED And Traditional Light Source Metal Halide Lamps (HID) In Plant Lighting?

6. What Are The Advantages And Disadvantages Of LED And Traditional Light Source Metal Halide Lamps (HID) In Plant Lighting?

High-pressure sodium lamps have been used in agricultural production for a long time, and LEDs have just begun to be used. However, as general lighting, LED market share is getting higher and higher, and many traditional lamps have been replaced by LEDs. This is an inevitable trend of technological development. However, the spectral output of metal halide lamps is relatively fixed, it is difficult to control the change of spectrum, so it is suitable for the growth of certain plants. At present, metal halide lamps are widely used in tomato planting, but if it is a plant factory, LED is better than it. Much more, its spectrum is more suitable. However, the current LED QE value is compared with metal halide lamps, LED has no obvious advantage.

7. What Is the Difference Between Hydroponic Vegetables And Plant Factories? Will There Be Insect Growth In Vegetable Plants?

Whether it is a greenhouse or an indoor artificial light factory, it will grow insects. The key is how to control, the greenhouse is a semi-manual control environment, if the state of the switch door is not well managed, there will be insects coming in, usually, there is a lot of space and insects come in. Plant factory management and greenhouse management are not a strict condition. We enter the plant factory and protect human hair. In addition, the air and water of the plant factory are purified or filtered. If strictly in accordance with the management model of the plant factory, The probability of long worms is very low, so pesticide plants are not allowed in plant factories. In greenhouses, we can only try to reduce the proportion of pollution, hydroponic cultivation through the nutrient solution is one of the methods.

On the basis of different light quality, how to ensure its luminous flux density? Also, how to make sure it is in the same light intensity. For example, red and blue light sources are combined into the same power, and the blue-chip is not the same as the red chip voltage chip. Different numbers seem to represent different light intensities, that is, PPF is different because of the luminous flux and plant chlorophyll. A and B have a relationship.

Even with the same PPF, the concept of light effect per watt is different. The influence of different spectra on plant growth is definitely different. Now many of the lamps sold in the market are measured by PPF per watt. I think this is Not comprehensive, because he does not contain the spectrum. Effective PPF is very important for plant growth spectroscopy.

We all know that in the design of the luminaire, it is very difficult to achieve complete uniformity of the spotlight of anyone lamp. It can only be realized by optical design at the stage of luminaire production, and the light is made more uniform as much as possible. Some linear lamps of power are doing very well. If you want to fill the light in the greenhouse, you need a more precise optical design.

8. When Conducting Plant Lighting Studies, Does The Light Test Performed Under The Same PPFD And The Different PPFDs Result In Different Final Test Results?

The same situation as PPFD compares the spectrum. If the PPFD is high or low, the spectrum is different, and the research results are basically not convincing. However, this depends on the direction of the research. If it is PPFD, the spectrum is different. This is the study of the spectrum. Some studies are different for PPFD, but the energy consumption is the same. The same lamps are used normally, such as each 20-watt lamp. Five lights are lit, and the adjustment of the height is compared to the difference in cultivation strength, which should be considered together. To learn more about LED plant lights, browse the following articles:《Is The LED Grow Lights Really Useful?》

To learn more about LED plant lights, browse the following articles:《Is The LED Grow Lights Really Useful?》

《The UV LED Technolog,Are You Using It In Right Ways?》

《Problems Should Be Avoided When Using The LED Grow Lights》

Planting the vegetables at home and eating fresh and healthy vegetables has become more and more a desire of urbanites. A “green oxygen bar” at home can not only increase vitality for the family but also relieve work stress.

However, most of the friends don't know how to grow them. It is often difficult to find a place where vegetables can be grown in the high-rise environment of the city. The home planting cabinet perfectly solves the above problems.

This article will show you and introduce the test situation of home planting, and provide a reference for everyone. On December 23, put the vegetable seeds you want to plant on a napkin, dump the water, keep it moist, pay attention to not too much water, and put the napkins together. It is well known that seed germination is respiration. After having a certain amount of water, we have to put the seeds in a dark place.《How To Effectively Improve Seed Germination Rate?》

On December 23, put the vegetable seeds you want to plant on a napkin, dump the water, keep it moist, pay attention to not too much water, and put the napkins together. It is well known that seed germination is respiration. After having a certain amount of water, we have to put the seeds in a dark place.《How To Effectively Improve Seed Germination Rate?》

On December 25th, the seeds sprouted white "buds", which is actually the root. Move the seeds into the Rockwool and pay attention to the white "buds" down. The rock face is placed in the planting basket, the sink is filled with water, and 5 packs of nutrient powder are placed. The nutrient powder can be dissolved in a disposable cup and then poured into the sink. The seed at this time needs photosynthesis, so it requires a certain amount of light. With LED growing lights, so turn on the lights directly, take about eight hours a day, remember to turn off at night.

On December 25th, the seeds sprouted white "buds", which is actually the root. Move the seeds into the Rockwool and pay attention to the white "buds" down. The rock face is placed in the planting basket, the sink is filled with water, and 5 packs of nutrient powder are placed. The nutrient powder can be dissolved in a disposable cup and then poured into the sink. The seed at this time needs photosynthesis, so it requires a certain amount of light. With LED growing lights, so turn on the lights directly, take about eight hours a day, remember to turn off at night. On December 27th, it seems that there is no movement in the quiet growth.

On December 27th, it seems that there is no movement in the quiet growth. On December 29th, the small leaf buds grew out.

On December 29th, the small leaf buds grew out. On January 1st, the leaf bud grew a little longer.

On January 1st, the leaf bud grew a little longer. On January 3, some of them were planted, and the small one was removed, leaving a big one. It seems to grow a little taller and grow a third leaf.

On January 3, some of them were planted, and the small one was removed, leaving a big one. It seems to grow a little taller and grow a third leaf.

On January 5th, the leaves were a little bigger. On January 7th, in order to grow better, some vegetables were transplanted into larger planters.

On January 7th, in order to grow better, some vegetables were transplanted into larger planters.

On January 9, a pack of nutritional powder was added.

On January 11, the local temperature dropped, and the vegetables grew a little slow. Fortunately, there were plant lights that extended the exposure time of the LED grow lights, about 12 hours a day.《How To Grow The Plants With LED Grow Lights?》 On January 15th.

On January 15th.

The vegetables grow very well and can't help but use one to make a salad, for the families dinner.

Summary: With the aid of tools, it is very easy to grow your favorite vegetables at home. At the same time, vegetables need sufficient light and nutrients during the planting process, so don't forget to turn on the LED plant lights and add the nutrient solution to the vegetables.

When we choose LED plant lights, in addition to the power, quality, and price, we will also pay attention to whether the products are in stock and can be shipped directly from the local warehouse. So when we choose LED grow lights on the website, is it better to ship from a local factory or from a local country?

Shipped From Local Factory

Advantages:

1. Generally, the factory shipments are made on site, and then sent to the customer the first time after the aging test. There is no need to accumulate in the warehouse, no need to worry about moisture, rust, damage to the circuit by the mouse, etc., the quality of the product is guaranteed.《Why The LED Grow Lights Need To Aging Test?》2. For customers of a custom type, the factory can adjust the material of the plant lamp according to the needs of the customer, the ratio of the lamp bead, etc., so that the light is better absorbed by the plant.

Disadvantages:

1. It takes longer to wait. From material preparation to product transportation to customers, it usually takes 7-15 waiting time. For customers who urgently need products, if the local factory delivers non-protest factors, including weather, peak season, need to the warehouse, customs clearance, etc. Affecting the timeliness of shipping, it may take longer than expected to receive the goods, resulting in a customer's unsatisfactory shopping experience.

2. Inconvenient return: If the product received by the customer is damaged due to violent transportation or other reasons, if you want to return the goods, the cost of returning the courier is more expensive, and the time is long. If the communication is not timely, the customer will have a bad impression. Influence subsequent cooperation. Shipped From The Local Country

Shipped From The Local Country

Advantages:

1. The delivery time is fast, generally only takes 3-5 days to be delivered, which is very suitable for customers who need urgently needed plant lighting.

2. The customer experience is better, no need to wait, if there is a return problem, it can be solved in the first time.

3. The logistics cost is lower, the shipping cost of the products arriving at the warehouses by sea is lower, which reduces the cost and helps the customers to buy affordable products.

Disadvantages:

1. Affected by the geographical location of the warehouse, the overseas warehouse has a limited range of products to choose from, which are generally applicable to small-sized and small-weight products such as plant par light.

2. Need to pay a certain storage fee

3. The product is easy to backlog, if the time is too long, it will affect the quality of the product.

Whether it is shipped from the factory or shipped from a local country, we should choose according to our actual needs. Xinjia not only has more than 100 workmates in the factory but also has overseas warehousesin the US, UK, RU, DE AU, etc., so customers do not need to worry about the above problems. Our overseas warehouses are our best-selling products, so we don't have to worry about product backlogs. At the same time, the factory delivers goods to meet the needs of different customers. If you have any questions, you can contact us:enquiry@ledgs.com

When we talk about mental health and happiness, poor lighting is often overlooked, and more often we focus on creating a happier, healthier workplace. However, poor lighting can have a number of negative effects on physical and mental health, such as eye fatigue, headaches, and anxiety. We spend most of our time in artificial lighting environments, and there is evidence that lack of natural light can adversely affect the body and mind and can lead to diseases such as seasonal affective disorder (SAD). When we spend the darkest days of the year, 40% of office workers struggle to work under the bad lights every day. According to a recent study on the impact of workplace lighting, this has a negative impact on their productivity and well-being. A recent study reported that an online survey of 7,000 office workers was conducted in October 2018. The study sample was from office workers in 10 European countries, including: UK (2000 people, 302 in London), Germany (1000), France (500), Netherlands (500), Sweden (500), Norway (500 people), Spain (500 people), Italy (500 people), Portugal (500 people) and Finland (500 people).

When we spend the darkest days of the year, 40% of office workers struggle to work under the bad lights every day. According to a recent study on the impact of workplace lighting, this has a negative impact on their productivity and well-being. A recent study reported that an online survey of 7,000 office workers was conducted in October 2018. The study sample was from office workers in 10 European countries, including: UK (2000 people, 302 in London), Germany (1000), France (500), Netherlands (500), Sweden (500), Norway (500 people), Spain (500 people), Italy (500 people), Portugal (500 people) and Finland (500 people).

80% of office workers say that good lighting is important to them in the workplace;

40% of people face uncomfortable lighting every day;

32% said that better lighting makes them happier at work.

However, when winter access to natural light is limited, many people feel stressed and even have the seasonal affective disorder (SAD), and often stay at their desks for long periods of time, which is sometimes the only daylighting opportunity in their day. The survey also showed that 25% of respondents were frustrated by the lack of light in the workplace.

In fact, usually, only 13-15 minutes of natural light is enough to trigger the release of endorphins or "happy hormones." Many scholars have concluded through long-term research that SAD affects 5% to 10% of the population, which accounts for a large proportion of clinical depression patients in a quarter of each year.

Another study concluded that there is a close relationship between workplace lighting and sleep, activity, and quality of life of office workers.

There is no clear standard in the UK for lighting levels in the workplace. However, there are also regulations that indicate that the lighting at the site should be “appropriate and adequate” and that natural light should be used in the workplace. The emphasis on natural daylighting and other related research reflects a consensus that daylight is the best form of lighting.

However, in parts of the northern hemisphere, daylight itself does not provide sufficient illumination for the entire work area. This means that “appropriate and sufficient” lighting often requires a combination of natural and artificial lighting, in particular, the need to provide individualized artificial lighting according to activities, functions and personal needs, as well as artificial lighting that mimics natural light.

Personalized lighting options help create a more inclusive work environment. One such method is to adjust the light intensity and illumination during the day based on the natural daylight level outdoors and the individual needs of the user. In this way, employees feel that they are more able to control their work environment, which has also been proven to improve their happiness and productivity in the workplace.

There is now ample evidence that lighting that mimics natural light can greatly improve the health and well-being of people in the workplace, such as providing more natural light through large windows to provide proper illumination, as well as providing biodynamics and Personalized lighting for task adjustment is achieved.

For areas where natural light is not available, choosing a suitable light is especially important. From this point of view, Xinjia designed LED lights of different power sizes. Customers can choose according to their own needs, not only can add enough light, but also save energy and save money. It is the best choice for your office and home. You may be interested in the following articles:《How To Choose A High Quality LED Corn Lights》

You may be interested in the following articles:《How To Choose A High Quality LED Corn Lights》

《Xinjia Teaches You How To Choose The Home Lighting!》

《What The Effects of Different Light Sources On Human Health?》

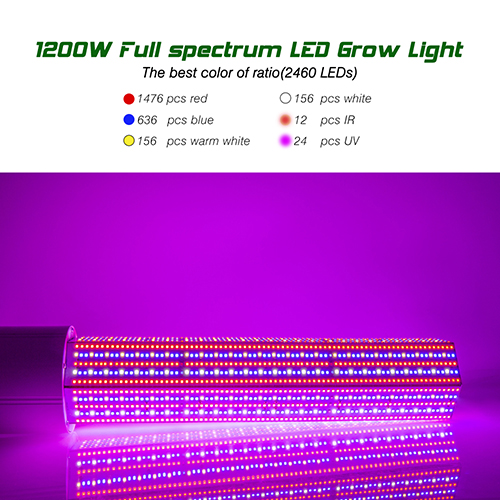

With the explosion of indoor and urban agriculture, LED energy conservation is not only attractive, but the advancement of UV LEDs makes the additional benefits of UV, especially UV-A and UV-B possible. Indoor agriculture. Ultraviolet light has been shown to promote an increase in plant production of active substances in medicinal plants, including the antioxidant benefits of many plants or the tetrahydrocannabinol content in cannabis. Ultraviolet light can also help maintain a healthy growing environment by reducing mold, mold and certain plant pests – all of which require alternative chemicals because of their enhanced germicidal capacity.

Although many of the LED grow lights used in indoor agriculture produce UV spectra to a certain extent, their external lens materials block most of them, and the actual amount of ultraviolet light reaching the plants is very small. As UV LED prices continue to fall, the target UV can be cost-effectively integrated into normal growth processes, and the correct wavelength, the correct dose, and the correct time in the life cycle of a particular plant species will improve.

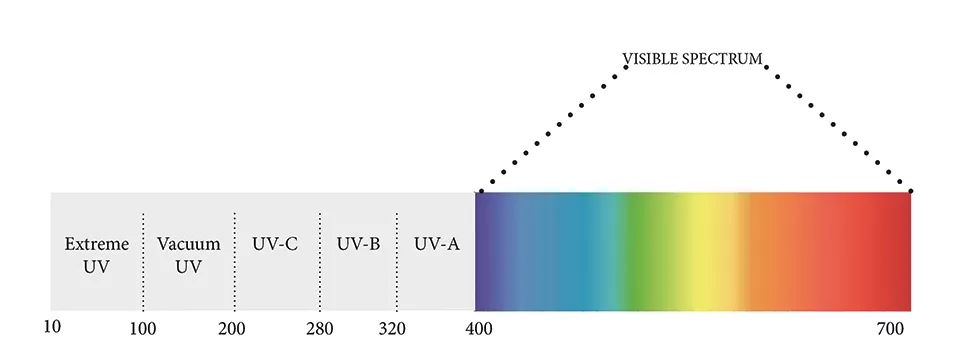

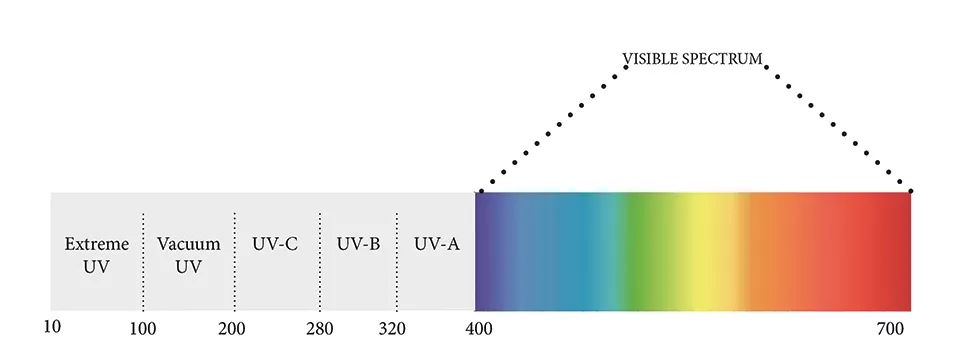

Ultraviolet (UV) light is a key part of the electromagnetic spectrum, with wavelengths ranging from 10 nm to 400 nm. This part of the spectrum is outside the visible range of the human eye, although insects and birds can perceive certain parts of the ultraviolet light. Most of the UV spectrum, including all extreme ultraviolet (10 nm-100 nm) and most of the spectra below 280 nm, is absorbed by the atmosphere. However, we artificially have the ability to generate these wavelengths, so it is still important to understand the benefits of each part of the UV spectrum. Ultraviolet Spectrum Classification

Ultraviolet Spectrum Classification

UV-C (200-280 nm): almost completely absorbed by the Earth's atmosphere, often used for its bactericidal effect.

UV-B (280-320 nm): About 95% UV-B is absorbed by the Earth's atmosphere and is often known for its associated risk of skin cancer. However, it has also been shown to have antibacterial effects, including treatment of agriculture. Infections and pests such as powdery mildew or spider aphids; and plant reactions that trigger the addition of flavonoids and cannabinoids.

UV-A (320-400 nm): commonly referred to as "black light", UV-A light has the longest wavelength in the ultraviolet spectrum and is considered to be the least hazardous, while it is capable of triggering the desired plant response. Applied to agriculture. Since the late 1990s, LEDs that transmit UV light in the upper range of the UV-A (390-420 nm) range have been available, typically for counterfeit testing or verification of driver's licenses or documents, and forensics. In fact, a large portion of the UV LED market is primarily for industrial and commercial applications for curing, such as inks, coatings or adhesives, typically accomplished by UV-A light having a wavelength of 350-390 nm.

Since the late 1990s, LEDs that transmit UV light in the upper range of the UV-A (390-420 nm) range have been available, typically for counterfeit testing or verification of driver's licenses or documents, and forensics. In fact, a large portion of the UV LED market is primarily for industrial and commercial applications for curing, such as inks, coatings or adhesives, typically accomplished by UV-A light having a wavelength of 350-390 nm.

When you enter the shorter wavelengths of UV-B and UV-C, the application turns to disinfect food, air, water, and surfaces. These are some of the latest wavelengths available in LEDs. LED energy savings are not only attractive to many industries, such as water purification, but their extremely small size makes them a very flexible option, including the ability to create portable disinfection systems.

In light of these advances, the UV LED market has expanded fivefold in the past decade and is expected to grow to $1.3 billion by 2025. A key trend expected to impact the market is to be able to further expand into new applications including solar products, the food and beverage industry and agriculture, such as LED plant lights. However, further improvements are still needed, particularly as it relates to lens assemblies for these products to ensure that the technology can achieve the desired results for each industry in a cost-effective manner.

With the explosion of indoor and urban agriculture, there is a growing desire to continue to improve the growth process in a cost-effective manner, which will still bring positive results to the target plants. Many existing studies on the use of LEDs in agriculture have focused on the wavelengths of visible light and the spectrum required by plants for various processes. In fact, many studies have been conducted to determine the relationship between different wavelengths and their effects. About plant growth. This information will help to further develop custom spectral lighting to deliver better results for plant plants at lower energy costs. For example, it has been determined that the red spectrum (630-660 nm) is essential for stem growth and leaf expansion, and is also an important wavelength for regulating flowering and dormancy.

The most advanced LED full-spectrum plant lights now offer more viable options for indoor planting, which can save a lot of costs, especially compared to traditional lighting options such as HPS.《LED Grow Lights VS High-Pressure Sodium Lamps,Which One Is The Most Efficient?》

《Is The LED Grow Lights Really Useful?》Ultraviolet light has also been shown to promote increased plant production of active substances in medicinal plants, including the antioxidant benefits of many plants or the tetrahydrocannabinol content in cannabis. Plants have chemical processes that enable them to recognize different wavelengths of light that trigger certain reactions, including ultraviolet reactions that can alter plant shape and alter the chemical composition.

One of the most common methods of plant response to ultraviolet light is the synthesis and accumulation of UV absorbing compounds. These compounds, including phenolic substances, act like a sunscreen to plants and prevent damage from excessive exposure to UV light. However, the benefits of phenolic compounds not only help protect plants but have also proven to have significant human health benefits, including antioxidant benefits and prevention of a variety of chronic diseases, including certain cancers and cardiovascular diseases.

Another plant known for its increased yield of pharmaceutical compounds under UV radiation is Cannabis sativa. Studies have found that higher levels of cannabinoids are found in plants at the lowest latitudes and high altitudes of the equator. Subsequent studies have shown that exposure of plants to UV-B results in an increase of Δ9-THC in leaf tissue by up to 48% and an increase in flower tissue by 32%.

The main threat faced by indoor growers is powdery mildew. However, UV has been shown to significantly reduce the mold of plants such as grapes, rose plants, cucumbers, rosemary, and strawberries. The researchers successfully reduced the severity of powdery mildew by 90-99% using an appropriate dose of UV-B. Over the past few decades, evidence supporting the benefits of UV protection of crops from mold, mold and other plant pests, as well as the ability to enhance the medicinal properties of plants, has increased dramatically. However, there are still significant challenges in how to successfully integrate UV into indoor growth facilities.

Over the past few decades, evidence supporting the benefits of UV protection of crops from mold, mold and other plant pests, as well as the ability to enhance the medicinal properties of plants, has increased dramatically. However, there are still significant challenges in how to successfully integrate UV into indoor growth facilities.

As the interior grows, it is important to determine the spectrum that best meets the needs of the plant, as the effects of different wavelengths depending on your location in the growth cycle and the specific plant species. For example, in the visible spectrum, a small portion of green light may be beneficial to support plant growth, but studies have shown it to be species-specific, with more than 50% potentially harmful effects. The same is true when UV is applied to agricultural lighting - you must be aware of the work you want to do for the plant.

When choosing LED lighting for plants, it's important to remember that although plants may not get too much light, they certainly produce too much heat. While LED grows lights are more efficient than other types of lamps, research has shown that UV LEDs only convert 15-25% of the received input power into light. The remainder is transferred as heat, so thermal management must be a critical part of the system.

As the price of UV LEDs continues to decrease, the ability to effectively incorporate UV light into the growth process will be greatly enhanced at the appropriate wavelengths, the right dose, and the appropriate time for the life cycle of a particular plant species. This reality will help further research and development of UV solutions, including determining the optimal combination of UV wavelengths and doses to achieve the desired effects of a particular plant species.

At present, Xinjia research has added a proper amount of UV lamp beads according to the needs of the spectrum, which will help the light to be better absorbed. Of course, we can also provide customized services according to your needs. We have more than ten years of professional experience and experience, it is our duty to provide customers with the most suitable plant lights. If necessary, please contactenquiry@ledgs.com