With the gradual maturity of the blue light LED technology and the introduction of intelligent control technology, Internet of things technology and sensing technology, the energy consumption of artificial light source has been greatly reduced, and intelligent plant lighting plants have gradually risen up. In 2017, Internet of things giant Beijing Orient built a plant lighting plant covering an area of 4,500 square meters in Beijing, using various LED plant lighting to supply light source for vegetables from breeding to maturity throughout the life cycle. This modern planting method overcomes the limitations of the geographical environment, effectively improves the growth efficiency of vegetables and greatly increases the yield of vegetables. Vegetables grown in this way can yield five times as much as those grown in traditional soil.

Back in the late 1980s, the United States built one of the world's largest mega-plant factories, Biosphere 2, a project designed to explore the feasibility of building closed ecosystems. Although the project ended in failure, it gained experience in new agricultural development and laid the foundation for the future construction of vertical aerial plant factories in the United States. Today, many U.S. cities are building plants and exporting the technology to places like the Middle East.

Today, the concept of intelligent and green environmental protection has been deeply rooted in the hearts of the people. It is a major trend of the future to combine high-tech and agriculture to create an intelligent agriculture that meets the needs of modern society. By biological technology, the Internet of things, big data, artificial intelligence, sensor technology and other high-tech technology together, and then on the basis of plant growth rule for precise control on the growth environment, so as to achieve optimization of plant growth, shorten the mature period, the purpose of increase production plants, rewrite the history of the traditional agriculture "weather", the new cultivation way has extremely far-reaching significance.

Although the advantages of plant lighting technology have been fully highlighted, there are still many obstacles to large-scale cultivation. Since a large amount of cost must be invested in the equipment at the initial stage, even if it can increase the output of vegetables, the vegetables grown are not significantly different from the traditional planting methods in taste and taste and do not have competitive advantages in pricing. Therefore, it cannot bring high profits to the enterprise quickly. Coupled with the lack of public understanding of plant lighting technology, it is difficult to open up the market acceptance, is bound to undergo a process of popularization.

To sum up, there are some problems in modern plant lighting, such as high technical barriers, a large investment in the early stage, high operation cost and long return cycle. These are all difficulties that need to be faced in the development and expansion of LED plant lighting industry, and enterprises will try their best to solve these problems.

Promising, Tech Giants Jump To 'Grow Vegetables'

The technical barriers to intelligent agriculture with the support of various new and high technologies are very high, so it is difficult for ordinary enterprises to get involved in this field. However, its broad market prospect has successfully attracted many well-known technology enterprises, including industrial giants GE, Siemens, LG, hon hai, TSMC and even well-known Internet companies like JD.com and Alibaba. On April 9 this year, the launching meeting of JD UAV opening & smart agriculture community was held at the headquarters of the JD group. JD hopes to build a smart agriculture open platform covering the whole upstream and downstream of the industry by integrating the group's logistics, finance, fresh food, big data and other capabilities. In June, GE announced the construction of a 5,120 square meter LED vertical farm in the UK. However, objectively speaking, intelligent agriculture is still in its early stage of development, and there is still a long way to go from large-scale industrialization.

Patterns and Challenges of LED Grow Lights Market

With the rapid growth of urban population, increasing demand for vegetables and decreasing land resources brought by urbanization, and the increasing environmental burden caused by traditional agricultural production methods, it is more and more important to seek breakthroughs beyond traditional planting methods. The way of plant lighting has incomparable advantages. Through intensive planting, it breaks through geographical and environmental constraints and can save resources to a greater extent, which is the general trend of future development.

At present, three major markets of LED plant lighting are planted factory, plant landscape, and breeding lighting. In terms of the global market, the United States, Japan, South Korea, the Netherlands and other countries are in a leading position in plant lighting. Due to Japan's problems of small land area, large population and the relative shortage of resources, plant lighting technology can well alleviate the pressure brought by the shortage of food, energy and land resources. Therefore, plant lighting technology has been highly valued in Japan, and the government has actively issued relevant policies to support, and directly provided more than 50% subsidies to the construction of plant factories and individuals. At present, Japan has the world's largest number of modern plant lighting factories, up to hundreds. With advanced technology and experience in plant lighting, Japan has been promoting the export of related technologies, and companies represented by Toshiba and Mitsubishi are actively promoting their related technologies to the sea.

Taiwan, China is a world-renowned "semiconductor kingdom" with a sound optoelectronic industry foundation. Plant factories started in Taiwan around 2010. In terms of resources, the situation of Taiwan is similar to that of Japan. Therefore, Taiwan chooses fine agriculture as its development director and has successfully entered the ranks of world advanced agriculture. Its plant factory products are supplied to many European countries.

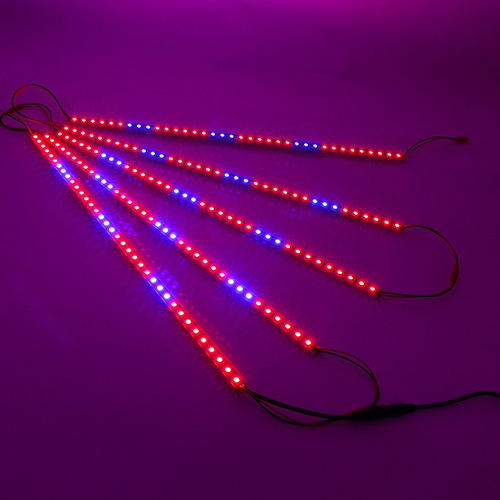

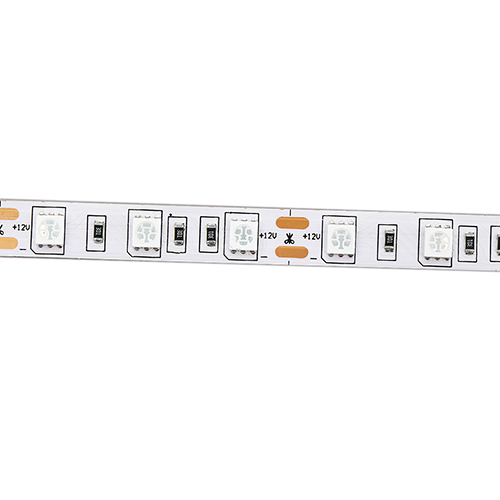

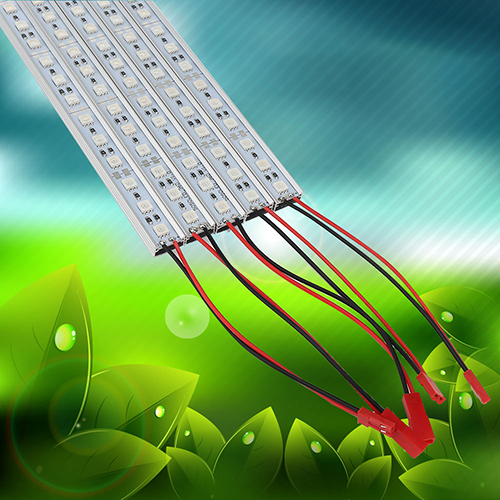

Although LED grow lights has a broad market space, there are still some shortcomings in specific applications. Because the LED lighting plants need comprehensive consideration, pipe distribution uniformity, light intensity and spectrum efficiency, such as heating elements, and plants need specific wavelengths, the needs of different varieties, growth cycle of light will also vary, so plant factory needs comprehensive content such as plant species, growth stage, timely adjust the best growth curve. The full-spectrum controllable ZW0210 product introduced by Sinjia perfectly satisfies the whole process of plant growth. Red, blue and full-spectrum lighting modes can be realized only by switching and adjustment. It is very easy and efficient to solve the adaptability problem of plant lamps.

Overall, there is a global consensus that the prospects for the plant lighting market are promising, and that an outbreak in the market would have a huge impact on the agricultural market.