2018年12月28日星期五

Does The Full Spectrum LED Grow Lights Harmful To Humans?

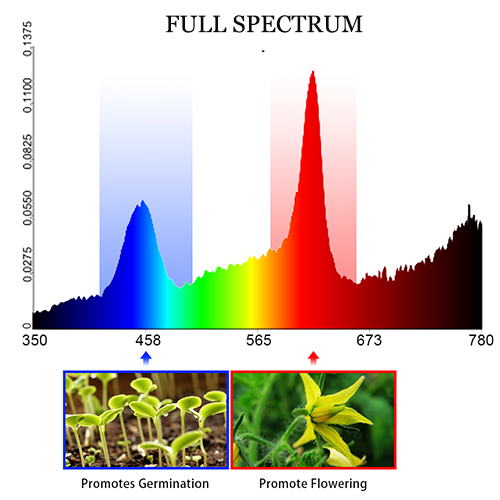

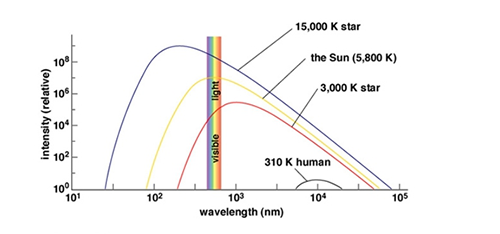

The full spectrum refers to the spectrum of ultraviolet, visible, and infrared light in the spectrum, and the ratio of red, green, and blue in the visible portion is similar to that of sunlight, and the color rendering index is close to that of 1. The spectrum of sunlight can be called the full spectrum. In the artificial light source, the amount of mercury is increased in the arc tube of the arc discharge gas discharge lamp, thereby increasing the light energy of the ultraviolet light portion, and adjusting the metal halide ratio to make the visible light portion The combination of wavelengths of each band is close to the solar spectrum, and the infrared portion of the wavelength is greater than 780. The spectrum is continuous and can last up to 1000 NM wavelength.

The color temperature of sunlight changes with the seasons and the time of morning and evening. Therefore, the spectrum of the full spectrum lamp should change the color temperature with time and simulate the natural light environment to better conform to the natural growth law of the organism.

The full spectrum of LED light sources has been developed internationally for many years. However, the current technology is limited to the development of continuous spectrum in the visible light region to improve the color rendering index, but it is difficult to achieve continuous spectrum in the ultraviolet and infrared portions. The spectrum of each UV and IR LED lamp bead is narrow, limited to a specific band, combined into a continuous spectrum, which is very difficult and costly.

Is The Blue Light In LED Growth Lights Harmful To Humans?

The LED plant light source is mainly composed of a red-blue light source, which uses the most sensitive light band of the plant, and the blue wavelength uses 450-460 nm and 460-470 nm.

Blue light is a relatively high-energy light with a wavelength between 400nm and 480nm. It is widely present in computer monitors, fluorescent lamps, mobile phones, digital products, displays, LEDs, etc. The blue light in this wavelength causes the macular area in the eye. The increased amount of toxins is a serious threat to our fundus health.

Specific hazards of blue light:

1. The blue light will aggravate the disease of the macular area of the retina. With the increase of age, the lipofuscin (cell debris) left by the phagocytosis of retinal pigment epithelial cells will gradually accumulate in the retinal pigment epithelial cell layer, which will cause the retina to illuminate the chronic light. More sensitive. The toxicity of the retina increases with the shortening of the wavelength after prolonged exposure, thereby aggravating the disease in the macula.

2.Blue light can cause fundus damage after cataract surgery with age, the body's own lens will gradually yellow.

3.Blue light can have blurred vision, leading to visual fatigue, causing VDT syndrome. When the blue light is incident on the fundus, the focus does not fall on the retina but falls between the retina and the lens, which increases the distance of the chromatic aberration of the light in the eye. The distance between the focal points in the eye is the main cause of blurring of the vision, so the injection of blue light will aggravate the chromatic aberration and visual ambiguity. When the eye muscles are too tight, the blood supply to the eyes is excessively tight, and the blood supply to the eyes is strengthened. Thereby aggravating fatigue.

4.Blue light can emit higher energy between 400nm and 500nm. Light with higher energy has a higher probability of scattering when it encounters fine particles in the air, and blue light becomes the main cause of glare.

5.Blue light can inhibit melatonin secretion, disturb sleep, improve the incidence of its own major diseases. Blue light is enough to stimulate the brain, making the brain excited, affecting the law of the biological clock, it takes too long to fall asleep, wake up many times during sleep Come to wait for insomnia symptoms. People with insufficient sleep or low quality sleep have significantly reduced immune function, responsiveness, memory, and coordination, and have an increased risk of diabetes, heart disease, cancer, obesity, indigestion, constipation, depression and other diseases.

Therefore, it is recommended that when using LED plant lights, do not look directly at the eyes, it is best to wear anti-radiation glasses.

Is UV in LED Growing Lamps Harmful To Humans?

Improper use of ultraviolet light can cause damage to the cornea leading to electro-optic ophthalmia:

When UV disinfection is carried out in public places, the energy carried is relatively large. Such short-wave ultraviolet lamps and consumers can choose a safe disinfection and sterilization method in various ways. In the absence of protective measures, use UV light carefully, and if the eyes and skin of the person are exposed to ultraviolet light for more than 3 minutes, it may cause skin cancer.

In plant lights, in order to make the spectrum more full, plants can grow better. Most designers will add UV beads, which has little effect on the human body, so you can use them with confidence.

The color temperature of sunlight changes with the seasons and the time of morning and evening. Therefore, the spectrum of the full spectrum lamp should change the color temperature with time and simulate the natural light environment to better conform to the natural growth law of the organism.

The full spectrum of LED light sources has been developed internationally for many years. However, the current technology is limited to the development of continuous spectrum in the visible light region to improve the color rendering index, but it is difficult to achieve continuous spectrum in the ultraviolet and infrared portions. The spectrum of each UV and IR LED lamp bead is narrow, limited to a specific band, combined into a continuous spectrum, which is very difficult and costly.

Is The Blue Light In LED Growth Lights Harmful To Humans?

The LED plant light source is mainly composed of a red-blue light source, which uses the most sensitive light band of the plant, and the blue wavelength uses 450-460 nm and 460-470 nm.

Blue light is a relatively high-energy light with a wavelength between 400nm and 480nm. It is widely present in computer monitors, fluorescent lamps, mobile phones, digital products, displays, LEDs, etc. The blue light in this wavelength causes the macular area in the eye. The increased amount of toxins is a serious threat to our fundus health.

Specific hazards of blue light:

1. The blue light will aggravate the disease of the macular area of the retina. With the increase of age, the lipofuscin (cell debris) left by the phagocytosis of retinal pigment epithelial cells will gradually accumulate in the retinal pigment epithelial cell layer, which will cause the retina to illuminate the chronic light. More sensitive. The toxicity of the retina increases with the shortening of the wavelength after prolonged exposure, thereby aggravating the disease in the macula.

2.Blue light can cause fundus damage after cataract surgery with age, the body's own lens will gradually yellow.

3.Blue light can have blurred vision, leading to visual fatigue, causing VDT syndrome. When the blue light is incident on the fundus, the focus does not fall on the retina but falls between the retina and the lens, which increases the distance of the chromatic aberration of the light in the eye. The distance between the focal points in the eye is the main cause of blurring of the vision, so the injection of blue light will aggravate the chromatic aberration and visual ambiguity. When the eye muscles are too tight, the blood supply to the eyes is excessively tight, and the blood supply to the eyes is strengthened. Thereby aggravating fatigue.

4.Blue light can emit higher energy between 400nm and 500nm. Light with higher energy has a higher probability of scattering when it encounters fine particles in the air, and blue light becomes the main cause of glare.

5.Blue light can inhibit melatonin secretion, disturb sleep, improve the incidence of its own major diseases. Blue light is enough to stimulate the brain, making the brain excited, affecting the law of the biological clock, it takes too long to fall asleep, wake up many times during sleep Come to wait for insomnia symptoms. People with insufficient sleep or low quality sleep have significantly reduced immune function, responsiveness, memory, and coordination, and have an increased risk of diabetes, heart disease, cancer, obesity, indigestion, constipation, depression and other diseases.

Therefore, it is recommended that when using LED plant lights, do not look directly at the eyes, it is best to wear anti-radiation glasses.

Is UV in LED Growing Lamps Harmful To Humans?

Improper use of ultraviolet light can cause damage to the cornea leading to electro-optic ophthalmia:

When UV disinfection is carried out in public places, the energy carried is relatively large. Such short-wave ultraviolet lamps and consumers can choose a safe disinfection and sterilization method in various ways. In the absence of protective measures, use UV light carefully, and if the eyes and skin of the person are exposed to ultraviolet light for more than 3 minutes, it may cause skin cancer.

In plant lights, in order to make the spectrum more full, plants can grow better. Most designers will add UV beads, which has little effect on the human body, so you can use them with confidence.

Is The Infrared Light In The Full Spectrum LED Growth Lights Harmful To The Human Body?

Customers who have an understanding of LED lights can find that there is actually no harm. In the market, there are LED RGB bulbs controlled by infrared rays. In our life, the remote control controls the TV by emitting infrared rays. The LED sensor lamps that are very popular by the public are also using the heat of the human body when the human body is approaching. Infrared detection works, so don't worry about the small amount of infrared light on the plant.

《Do LED Lights Harmful To Human Health?》

Customers who have an understanding of LED lights can find that there is actually no harm. In the market, there are LED RGB bulbs controlled by infrared rays. In our life, the remote control controls the TV by emitting infrared rays. The LED sensor lamps that are very popular by the public are also using the heat of the human body when the human body is approaching. Infrared detection works, so don't worry about the small amount of infrared light on the plant.

《Do LED Lights Harmful To Human Health?》

2018年12月27日星期四

The Fill Light Method And Development Direction of Plant Factory

The plant factory combines modern industry, biotechnology, nutrient solution cultivation and information technology to implement high-precision control of environmental factors in the facility. It has full closure, low requirements for the surrounding environment, shortens plant harvest period, saves water and fertilizer, and has no The advantages of pesticide production and non-discharge of waste are 40~108 times of the production efficiency of open land. An intelligent artificial light source and its light environment control play a decisive role in its production efficiency.

As an important physical environmental factor, light plays a key role in regulating plant growth and material metabolism. “One of the main features of plant factories is the full artificial light source and the intelligent regulation of the light environment” has become a common consensus in the industry.

Plant Demand For Light

Plant life activities are inseparable from light. Light is the only source of energy for plant photosynthesis. Light intensity, light quality (spectrum) and periodic changes of light have a profound impact on crop growth and development, and photosynthesis of plants by light intensity The effect is the biggest.

Light Intensity

The intensity of light can change the shape of the crop, such as flowering, internode length, stem thickness, and leaf size and thickness. Plants' requirements for light intensity can be divided into hi-light, hi-light, and low-light plants. Most of the vegetables belong to hi-light plants, and their light compensation points and light saturation points are relatively high. In the artificial light plant factory, the relevant requirements of crop light intensity are an important basis for selecting artificial light sources. Understanding the illumination requirements of different plants is to design artificial light sources. Improving the production performance of the system is extremely necessary.

Light Quality

Light quality (spectral) distribution also has an important impact on plant photosynthesis and morphogenesis. Light is part of the radiation, and radiation is an electromagnetic wave. Electromagnetic waves have wave characteristics and quantum (particle) characteristics. The quantum of light is called photon, and it is also called photon in the field of horticulture. Radiation with a wavelength range of 300-800 nm is called physiologically active radiation of a plant, and radiation with a wavelength range of 400-700 nm is called photosynthetically active radiation (PAR) of a plant.

Photoperiod

The relationship between photosynthesis and photomorphogenesis of plants and the length of day (or light period) is called the photoperiod of plants. Periluminality is closely related to the number of hours of illumination, and the number of hours of illumination refers to the time when the crop is illuminated by light. Different crops require a certain amount of light hours to complete the photoperiod. According to the different photoperiod, it can be divided into long-day crops, such as cabbage, which require more than 12~14h of light hours at a certain stage of birth; short-day crops, such as onions and soybeans, need 12~14h or less. Light hours; medium-day crops, such as cucumbers, tomatoes, peppers, etc., can bloom and bear under long or short sunshine.

Among the three elements of the environment, the light intensity is an important basis for selecting artificial light sources. At present, there are various expression methods for light intensity, including the following three types.

(1) Illumination refers to the luminous flux surface density (luminous flux per unit area) accepted on the illuminated plane, in units of lux (lx).

(2) Photosynthetically active irradiance PAR, unit: W/m² .

(3) Photosynthetically active photon quantum density PPFD or PPF is the photon number of photosynthetically active radiation arriving or passing per unit time per unit area, in units of μmol/(m²·s). Mainly refers to the light intensity of 400~700nm directly related to photosynthesis. It is also the most commonly used indicator of light intensity in the field of plant production.

Light Source Analysis Of Typical Fill Light System

The artificial fill light is achieved by installing a fill light system to increase the light intensity in the target area or prolong the illumination time to achieve the plant's light demand. In general, fill light systems include fill light devices, circuits, and their control systems. The fill light source mainly includes several common types such as incandescent lamp, fluorescent lamp, metal halide lamp, high-pressure sodium lamp and LED plant lamp. Due to the low efficiency of incandescent lamps and low efficiency of photosynthetic energy, they have been eliminated by the market.

Fluorescent Lamp

Fluorescent lamps are a type of low-pressure gas discharge lamp. The glass tube is filled with mercury vapor or an inert gas, and the inner wall of the tube is coated with a phosphor, and the color of the light varies depending on the fluorescent material applied in the tube. The fluorescent lamp has good spectral performance, high luminous efficiency, low power, long life (12000h) compared with incandescent lamps, and relatively low cost. Because the fluorescent lamp itself generates less heat, it can be placed close to the plant for illumination. It is suitable for three-dimensional cultivation, but the spectral layout of the fluorescent lamp is unreasonable. The internationally common method is to add a reflector to maximize the effective light source component of the crop in the cultivation area. Japan's adv-agri company has also developed a new fill light source HEFL. HEFL is actually a category of fluorescent lamps. It is a general term for cold cathode fluorescent lamps (CCFL) and external electrode fluorescent lamps (EEFL). The HEFL lamp is extremely thin, with a diameter of only about 4mm. The length can be adjusted from 450mm to 1200mm according to the cultivation needs. It is an improved version of the conventional fluorescent lamp.

Metal Halide

The metal halide lamp is a high-intensity discharge lamp which is formed by adding various metal halides (tin bromide, sodium iodide, etc.) to the discharge tube to generate different wavelengths on the basis of the high-pressure mercury lamp. The halogen lamp has high luminous efficiency, high power, good light color, high life, and a large spectrum. However, since the luminous efficiency is lower than that of the high-pressure sodium lamp, the life is shorter than that of the high-pressure sodium lamp, and it is currently used only in a few plant factories.

HPS

High-pressure sodium lamps are of the type of high-pressure gas discharge lamps. The high-pressure sodium lamp is a high-efficiency lamp in which a high-pressure sodium vapor is charged in a discharge tube and a small amount of cesium (Xe) and a halide of a mercury lamp metal is added. Because high-pressure sodium lamps have high electro-optical conversion efficiency and low manufacturing cost, high-pressure sodium lamps are the most widely used in agricultural facilities for light-filling applications. However, due to the shortcomings of low photosynthetic efficiency, low-efficiency short-boards are caused. On the other hand, the spectral components emitted by high-pressure sodium lamps are mainly concentrated in the yellow-orange light band, lacking the red and blue spectrum necessary for plant growth.

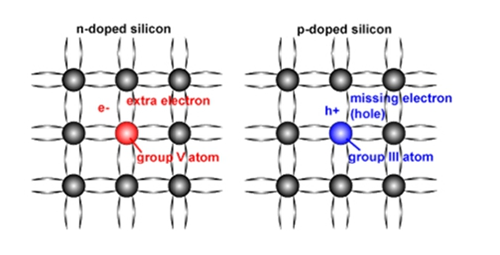

LED

As a new generation of the light source, light-emitting diode (LED) has higher electro-optical conversion efficiency, adjustable spectrum and high photosynthetic efficiency. LED can emit monochromatic light required for plant growth. Compared with ordinary fluorescent lamps and other complementary light sources, LEDs have the advantages of energy saving, environmental protection, long life, monochromatic light, and cold light source. As the electro-optical efficiency of LEDs further increases, the cost of scale effects decreases, and LEDs will become the mainstream equipment for agricultural facilities.

By comparison, the characteristics of different fill light sources can be clearly understood, as shown in Table 1.

Want to learn more about LED plant lights? You can click on the article:

《Can Be Eaten The Vegetable Which Grows With The LED Grow Lights》

《The Prospects of LED Grow Lights For Development 》

《Why We Need LED Grow Lights?》

The Design Idea of Typical Crop Fill Light System

The design of the plant factory fill light system is usually designed with the core content of the light intensity, light quality and photoperiod parameters of different crop growth stages and special means of end regulation, and relies on the intelligent control system to implement the implementation, achieving the ultimate goal of energy saving and high yield.

At present, the design of the fill light design for leafy vegetables has gradually matured. For example, leafy vegetables can be divided into four stages: seedling stage, middle growth stage, late growth stage, and terminal treatment; fruit vegetables can be divided into the seedling stage, vegetative growth stage, flowering stage and harvesting stage. From the light intensity of the fill light, the light intensity at the seedling stage should be slightly lower, at 60~200 μmol/(m?·s), and then gradually increase. Leaf vegetables can reach up to 100~200 μmol/(m?·s), fruit vegetables can reach 300~500 μmol/(m?·s), to ensure the photosynthesis requirements of photosynthesis in different growth stages, and to achieve high yield. For the light quality, the ratio of red to blue is crucial. In order to increase the quality of the seedlings and prevent the length of the seedlings, the ratio of red and blue is generally set at a lower level [(1~2): 1], and then gradually reduced to meet the needs of plant light form formation, and the leaf red and blue ratio can be compared. Settings (3~6): 1. For the photoperiod, similar to the light intensity, it should show an increasing trend with the extension of the growth period, so that the leafy vegetables have more photosynthesis time for photosynthesis. The light-filling design of fruit and vegetables will be more complicated. In addition to the above basic rules, we should focus on the photoperiod setting during flowering, and we must promote the flowering results of vegetables so as not to be counterproductive.

It is worth mentioning that the light formula should include the end-disposal light environment setting content, for example, the continuous supplementation of light can greatly improve the yield and quality of the hydroponic vegetable seedlings, or the UV treatment can significantly improve the sprouts and leafy vegetables (especially The nutritional quality of purple leaves and red leaf lettuce).

It is not difficult to find that the LED light source equipment is most in line with the current development trend in order to cope with the weak light and ultraviolet light caused by bad weather such as cloudy weather and haze and to ensure high-yield and stable production of facility crops.

In the future, the development direction of plant factories should be re-typed with high-precision, low-cost sensors and remotely controllable, tunable spectral fill light system and expert control system. At the same time, the future plant factory will continue to develop with low cost, intelligence, and adaptability. The use and popularization of LED light source provide high-precision environmental control for plant factories. LED light environment regulation is a complex process involving light quality, light intensity, photoperiod, and other comprehensive control. It is believed that with the further research of LED fill light illumination and With the promotion, plant factories will play an important role in our lives.

《The Analysis of Vertical Farm Development Prospect》

《How To Build A Successful Plant Factory?》

《The Problems In Greenhouse And How To Solve Them?》

As an important physical environmental factor, light plays a key role in regulating plant growth and material metabolism. “One of the main features of plant factories is the full artificial light source and the intelligent regulation of the light environment” has become a common consensus in the industry.

Plant Demand For Light

Plant life activities are inseparable from light. Light is the only source of energy for plant photosynthesis. Light intensity, light quality (spectrum) and periodic changes of light have a profound impact on crop growth and development, and photosynthesis of plants by light intensity The effect is the biggest.

Light Intensity

The intensity of light can change the shape of the crop, such as flowering, internode length, stem thickness, and leaf size and thickness. Plants' requirements for light intensity can be divided into hi-light, hi-light, and low-light plants. Most of the vegetables belong to hi-light plants, and their light compensation points and light saturation points are relatively high. In the artificial light plant factory, the relevant requirements of crop light intensity are an important basis for selecting artificial light sources. Understanding the illumination requirements of different plants is to design artificial light sources. Improving the production performance of the system is extremely necessary.

Light Quality

Light quality (spectral) distribution also has an important impact on plant photosynthesis and morphogenesis. Light is part of the radiation, and radiation is an electromagnetic wave. Electromagnetic waves have wave characteristics and quantum (particle) characteristics. The quantum of light is called photon, and it is also called photon in the field of horticulture. Radiation with a wavelength range of 300-800 nm is called physiologically active radiation of a plant, and radiation with a wavelength range of 400-700 nm is called photosynthetically active radiation (PAR) of a plant.

Photoperiod

The relationship between photosynthesis and photomorphogenesis of plants and the length of day (or light period) is called the photoperiod of plants. Periluminality is closely related to the number of hours of illumination, and the number of hours of illumination refers to the time when the crop is illuminated by light. Different crops require a certain amount of light hours to complete the photoperiod. According to the different photoperiod, it can be divided into long-day crops, such as cabbage, which require more than 12~14h of light hours at a certain stage of birth; short-day crops, such as onions and soybeans, need 12~14h or less. Light hours; medium-day crops, such as cucumbers, tomatoes, peppers, etc., can bloom and bear under long or short sunshine.

Among the three elements of the environment, the light intensity is an important basis for selecting artificial light sources. At present, there are various expression methods for light intensity, including the following three types.

(1) Illumination refers to the luminous flux surface density (luminous flux per unit area) accepted on the illuminated plane, in units of lux (lx).

(2) Photosynthetically active irradiance PAR, unit: W/m² .

(3) Photosynthetically active photon quantum density PPFD or PPF is the photon number of photosynthetically active radiation arriving or passing per unit time per unit area, in units of μmol/(m²·s). Mainly refers to the light intensity of 400~700nm directly related to photosynthesis. It is also the most commonly used indicator of light intensity in the field of plant production.

Light Source Analysis Of Typical Fill Light System

The artificial fill light is achieved by installing a fill light system to increase the light intensity in the target area or prolong the illumination time to achieve the plant's light demand. In general, fill light systems include fill light devices, circuits, and their control systems. The fill light source mainly includes several common types such as incandescent lamp, fluorescent lamp, metal halide lamp, high-pressure sodium lamp and LED plant lamp. Due to the low efficiency of incandescent lamps and low efficiency of photosynthetic energy, they have been eliminated by the market.

Fluorescent Lamp

Fluorescent lamps are a type of low-pressure gas discharge lamp. The glass tube is filled with mercury vapor or an inert gas, and the inner wall of the tube is coated with a phosphor, and the color of the light varies depending on the fluorescent material applied in the tube. The fluorescent lamp has good spectral performance, high luminous efficiency, low power, long life (12000h) compared with incandescent lamps, and relatively low cost. Because the fluorescent lamp itself generates less heat, it can be placed close to the plant for illumination. It is suitable for three-dimensional cultivation, but the spectral layout of the fluorescent lamp is unreasonable. The internationally common method is to add a reflector to maximize the effective light source component of the crop in the cultivation area. Japan's adv-agri company has also developed a new fill light source HEFL. HEFL is actually a category of fluorescent lamps. It is a general term for cold cathode fluorescent lamps (CCFL) and external electrode fluorescent lamps (EEFL). The HEFL lamp is extremely thin, with a diameter of only about 4mm. The length can be adjusted from 450mm to 1200mm according to the cultivation needs. It is an improved version of the conventional fluorescent lamp.

Metal Halide

The metal halide lamp is a high-intensity discharge lamp which is formed by adding various metal halides (tin bromide, sodium iodide, etc.) to the discharge tube to generate different wavelengths on the basis of the high-pressure mercury lamp. The halogen lamp has high luminous efficiency, high power, good light color, high life, and a large spectrum. However, since the luminous efficiency is lower than that of the high-pressure sodium lamp, the life is shorter than that of the high-pressure sodium lamp, and it is currently used only in a few plant factories.

HPS

High-pressure sodium lamps are of the type of high-pressure gas discharge lamps. The high-pressure sodium lamp is a high-efficiency lamp in which a high-pressure sodium vapor is charged in a discharge tube and a small amount of cesium (Xe) and a halide of a mercury lamp metal is added. Because high-pressure sodium lamps have high electro-optical conversion efficiency and low manufacturing cost, high-pressure sodium lamps are the most widely used in agricultural facilities for light-filling applications. However, due to the shortcomings of low photosynthetic efficiency, low-efficiency short-boards are caused. On the other hand, the spectral components emitted by high-pressure sodium lamps are mainly concentrated in the yellow-orange light band, lacking the red and blue spectrum necessary for plant growth.

LED

As a new generation of the light source, light-emitting diode (LED) has higher electro-optical conversion efficiency, adjustable spectrum and high photosynthetic efficiency. LED can emit monochromatic light required for plant growth. Compared with ordinary fluorescent lamps and other complementary light sources, LEDs have the advantages of energy saving, environmental protection, long life, monochromatic light, and cold light source. As the electro-optical efficiency of LEDs further increases, the cost of scale effects decreases, and LEDs will become the mainstream equipment for agricultural facilities.

By comparison, the characteristics of different fill light sources can be clearly understood, as shown in Table 1.

Want to learn more about LED plant lights? You can click on the article:

《Can Be Eaten The Vegetable Which Grows With The LED Grow Lights》

《The Prospects of LED Grow Lights For Development 》

《Why We Need LED Grow Lights?》

The Design Idea of Typical Crop Fill Light System

The design of the plant factory fill light system is usually designed with the core content of the light intensity, light quality and photoperiod parameters of different crop growth stages and special means of end regulation, and relies on the intelligent control system to implement the implementation, achieving the ultimate goal of energy saving and high yield.

At present, the design of the fill light design for leafy vegetables has gradually matured. For example, leafy vegetables can be divided into four stages: seedling stage, middle growth stage, late growth stage, and terminal treatment; fruit vegetables can be divided into the seedling stage, vegetative growth stage, flowering stage and harvesting stage. From the light intensity of the fill light, the light intensity at the seedling stage should be slightly lower, at 60~200 μmol/(m?·s), and then gradually increase. Leaf vegetables can reach up to 100~200 μmol/(m?·s), fruit vegetables can reach 300~500 μmol/(m?·s), to ensure the photosynthesis requirements of photosynthesis in different growth stages, and to achieve high yield. For the light quality, the ratio of red to blue is crucial. In order to increase the quality of the seedlings and prevent the length of the seedlings, the ratio of red and blue is generally set at a lower level [(1~2): 1], and then gradually reduced to meet the needs of plant light form formation, and the leaf red and blue ratio can be compared. Settings (3~6): 1. For the photoperiod, similar to the light intensity, it should show an increasing trend with the extension of the growth period, so that the leafy vegetables have more photosynthesis time for photosynthesis. The light-filling design of fruit and vegetables will be more complicated. In addition to the above basic rules, we should focus on the photoperiod setting during flowering, and we must promote the flowering results of vegetables so as not to be counterproductive.

It is worth mentioning that the light formula should include the end-disposal light environment setting content, for example, the continuous supplementation of light can greatly improve the yield and quality of the hydroponic vegetable seedlings, or the UV treatment can significantly improve the sprouts and leafy vegetables (especially The nutritional quality of purple leaves and red leaf lettuce).

It is not difficult to find that the LED light source equipment is most in line with the current development trend in order to cope with the weak light and ultraviolet light caused by bad weather such as cloudy weather and haze and to ensure high-yield and stable production of facility crops.

In the future, the development direction of plant factories should be re-typed with high-precision, low-cost sensors and remotely controllable, tunable spectral fill light system and expert control system. At the same time, the future plant factory will continue to develop with low cost, intelligence, and adaptability. The use and popularization of LED light source provide high-precision environmental control for plant factories. LED light environment regulation is a complex process involving light quality, light intensity, photoperiod, and other comprehensive control. It is believed that with the further research of LED fill light illumination and With the promotion, plant factories will play an important role in our lives.

《The Analysis of Vertical Farm Development Prospect》

《How To Build A Successful Plant Factory?》

《The Problems In Greenhouse And How To Solve Them?》

2018年12月23日星期日

Problems Should Be Avoided When Using The LED Grow Lights

Many people around the world are growing marijuana at home, whether for entertainment or medical purposes, although some of them do well and produce good products, for others, they don't work well. In this article, we will provide you with the most common things you should be aware of when using LED grow lights so that you can grow healthy plants and avoid any unnecessary hassles. This information is very relevant to beginners.

1.Too Much Heat

If the leaves closest to the light begin to brown, you will know that the plant is taking too much heat. If some of the leaves begin to curl, it may also indicate that the plants are too close to the light. Good ventilation usually helps solve this problem, and experienced growers install electric fans in grow tents to help plants dissipate more quickly.

2.Insufficient Lighting

Planting areas of different sizes need to choose plant lights of different powers, think about how many plants you are planting, and how many LED lights you need to properly illuminate them. You should also know the brightness of the light you are using.

3.A Wrong Distance Between Lamp and Plant

Excessive light or insufficient light may be due to the light being too close or too far from the plant. There is no optimal standard for setting the distance but it is recommended to place the LED 12 to 18 inches from the plant and adjust the appropriate distance according to the growth rate of the plant. Another important thing is to occasionally rotate the flower pot to prevent uneven illumination. Causes the plant to tilt too much.

《How To Control The Irradiation Distance And Time Of LED Grow Lights?》

4. Choose inferior products

Light is the most important factor in plant growth because it triggers photosynthesis processes. If you use ordinary incandescent lamps, you are unlikely to grow strong, healthy plants. Therefore, for best results, we recommend using a full spectrum LED growing lights. Designed specifically for this purpose, they have the ability to provide illumination in the precise spectral range required by the factory.

《How To Choose The Suitable LED Grow Light For Our Plants?》

1.Too Much Heat

If the leaves closest to the light begin to brown, you will know that the plant is taking too much heat. If some of the leaves begin to curl, it may also indicate that the plants are too close to the light. Good ventilation usually helps solve this problem, and experienced growers install electric fans in grow tents to help plants dissipate more quickly.

2.Insufficient Lighting

Planting areas of different sizes need to choose plant lights of different powers, think about how many plants you are planting, and how many LED lights you need to properly illuminate them. You should also know the brightness of the light you are using.

3.A Wrong Distance Between Lamp and Plant

Excessive light or insufficient light may be due to the light being too close or too far from the plant. There is no optimal standard for setting the distance but it is recommended to place the LED 12 to 18 inches from the plant and adjust the appropriate distance according to the growth rate of the plant. Another important thing is to occasionally rotate the flower pot to prevent uneven illumination. Causes the plant to tilt too much.

《How To Control The Irradiation Distance And Time Of LED Grow Lights?》

4. Choose inferior products

Light is the most important factor in plant growth because it triggers photosynthesis processes. If you use ordinary incandescent lamps, you are unlikely to grow strong, healthy plants. Therefore, for best results, we recommend using a full spectrum LED growing lights. Designed specifically for this purpose, they have the ability to provide illumination in the precise spectral range required by the factory.

《How To Choose The Suitable LED Grow Light For Our Plants?》

5.Choosing The Wrong Spectrum

For efficient growth, plants require different types of light at each stage of growth. This is easy to achieve with full-spectrum LED grow lights, but if you choose the wrong settings, the factory will not develop well. You should also consider the conditions of the room you are growing up. For example, plants are most benefiting from the blue spectrum when plants are in the vegetative stage of growth. This means that if you set the light to emit light in the red spectrum, it will only hinder the growth of the plant.

6. Lighting Usage Is Incorrect

You may forget to turn on these plant lights because time is too busy. On the contrary, or forget to close them, this may sound insignificant, but the wrong arrangement is likely to adversely affect the growth of plants. In fact, cannabis requires approximately 18-24 hours of illumination during the vegetative phase and 12 hours of illumination during the flowering phase.

7. Do Not Protect And Maintain LED Lights

LED growth lights are your friends and important investments, so you need to keep them in a safe place. They bring a lot of benefits to the evolving process, and a little maintenance and preparation can save you a lot of trouble.

How to maintain LED lights? Click on the following article for details:

《5 Ways To Maintain LED Lights》

8.Other Factors

In fact, indoor cannabis cultivation saves us a lot of trouble, but we still need to consider many factors such as room temperature, air circulation, soil, nutrients, plant genetics, etc. during the growth of plants. A little more patience with the plants, care, plants will give us unexpected returns.

2018年12月21日星期五

Four Major Trends of LED Lighting in 2019

In the twinkling of an eye, 2018 is about to pass, and we will usher in a new 2019. So, what are the LED lighting trends in 2019?

Customized Service

One of the best ways to give space and personality is to use unique lighting fixtures. “Designers like to be able to customize a decorative element to match any environment.” Chandeliers take custom trends to a new level, with a variety of sizes and countless combinations of colors to create thousands of unique looks.

Light But Not See It

Modern interior design is based on simplicity and cleanliness, so the smallest lines and seamless lighting design will be at the forefront of lighting design in 2019. “Unless the purpose of the luminaire is to decorate, it is important to feel the lighting and not to see the lighting.” Incorporating the lighting into the building is impressive and allows you to experience the purest space.

Toning

As LED lighting and control become more popular, the possibilities are also increasing. One of the new possibilities is the ability to change the color temperature and illumination level in space. “As a trend, color correction is being accepted by the design industry”, “is a good application for hotels and restaurants, even schools.” The current color palette is known to the public as RGB balls. Bulbs: By changing the color of the bulbs, simple operation is the best choice for Christmas and other holiday parties.

Wireless Function

“People like to be able to control each fixture from a single source,” “but the greater benefit is lowering the labor and installation costs of wireless systems.” With a single platform, setup, configuration, and system maintenance can all be handled by mobile devices. , making connected lighting easier to implement in commercial or industrial applications.

The products produced by Xinjia have been following the development of the times. The latest LED grow lights can be directly controlled by the remote control, allowing you to provide light to your plants remotely. At the same time, we will also launch mobile phone remote control plant lights in 2019, so stay tuned.

《12 Advantages of LED Lights》

《The Analysis of LED Grow Lights's Market Growth》

《The Best LED Grow Light of 2018》

Customized Service

One of the best ways to give space and personality is to use unique lighting fixtures. “Designers like to be able to customize a decorative element to match any environment.” Chandeliers take custom trends to a new level, with a variety of sizes and countless combinations of colors to create thousands of unique looks.

Light But Not See It

Modern interior design is based on simplicity and cleanliness, so the smallest lines and seamless lighting design will be at the forefront of lighting design in 2019. “Unless the purpose of the luminaire is to decorate, it is important to feel the lighting and not to see the lighting.” Incorporating the lighting into the building is impressive and allows you to experience the purest space.

Toning

As LED lighting and control become more popular, the possibilities are also increasing. One of the new possibilities is the ability to change the color temperature and illumination level in space. “As a trend, color correction is being accepted by the design industry”, “is a good application for hotels and restaurants, even schools.” The current color palette is known to the public as RGB balls. Bulbs: By changing the color of the bulbs, simple operation is the best choice for Christmas and other holiday parties.

Wireless Function

“People like to be able to control each fixture from a single source,” “but the greater benefit is lowering the labor and installation costs of wireless systems.” With a single platform, setup, configuration, and system maintenance can all be handled by mobile devices. , making connected lighting easier to implement in commercial or industrial applications.

The products produced by Xinjia have been following the development of the times. The latest LED grow lights can be directly controlled by the remote control, allowing you to provide light to your plants remotely. At the same time, we will also launch mobile phone remote control plant lights in 2019, so stay tuned.

《12 Advantages of LED Lights》

《The Analysis of LED Grow Lights's Market Growth》

《The Best LED Grow Light of 2018》

2018年12月19日星期三

LED Plant Factory - A New Direction For The Development Of Smart Agriculture

Japan's smart agriculture is characterized by information technology, which solves the problem of less labor in Japan and realizes the transformation and upgrading of the agricultural industry. Japan attaches great importance to the cultivation of talents and has successfully transformed and upgraded the agricultural industry with the help of agricultural information networks, agricultural database systems, precision agriculture, bioinformatics, and e-commerce. Learning from the development of smart agriculture in Japan can provide a better reference for the development of smart agriculture in the world.

Computer Farming During The Day, Robots On Duty At Night

Located in Fujita's "Autumn" smart farm in Putian City, Shizuoka Prefecture, Japan, the Autumn Color Farm covers an area of 85,000 square meters and has 12 football fields. There are many vegetable greenhouses up to 6 meters in the park, and the exterior is all glass. The steel frame structure at the top of the greenhouse is also very small, the farm official said, this is to ensure a larger area of light.

Before entering the greenhouse where one of the colorful peppers is grown, the staff wears a plastic jacket, rubber gloves and disinfection of the soles and hands. It is strictly forbidden to touch the plants by hand to ensure that the environment is as sterile as possible.

Rows of plant plants are cultivated in dedicated artificially cultivated soil, and water, nutrient solution, and carbon dioxide are connected through the pipeline from the bottom. The branches of the colored peppers continue to grow along the hanging steel wire, and the staff needs a special lift truck to enter the rows of plants for picking. The humidity and nutrient supply in the greenhouse are controlled by computers.

Qiu Cai Farm Specialist Ito Shengmin said that Qiu Cai Farm was jointly established by a well-known Japanese IT company Fujitsu and an agricultural finance company and a local seed research and development company in Putian in 2016. At present, Qiu Cai Farm has initially realized the high degree of automation of environmental control and the visualization of operation management. The staff can observe the temperature, humidity, and daily light of the greenhouse in real time through multiple displays in the main building to realize remote operation and cloud data. Japanese typhoons are frequent. When a typhoon strikes, the staff can remotely control the skylights in the greenhouse.

In the greenhouse, there are self-propelled robots walking along the track at night, using LED growing Lights to provide additional light to the greenhouse, monitoring the plants with other equipment, and forming a photosynthesis color image for the staff to adjust the temperature and humidity.

"Plant Factory" Into Investment Hot

The so-called "plant factory" uses the computer to automatically control the environmental conditions such as temperature, humidity, light, carbon dioxide concentration and nutrient solution of plant growth, and realizes mass production of plants in a short period of time and a small space to realize crops. Efficient agricultural systems for continuous production. The concept of “plant factory” first appeared in Northern Europe, but it was first applied in Japan on a large scale. There are currently more than 400 artificial plant factories in the world, half of which are in Japan.

Located in a plant in Chiba Prefecture, in a two-story building surrounded by vegetable greenhouses in the National Chiba University campus, the 74-year-old director of the Japan Plant Factory Research Society, said in the tree plant, the plant is a closed environment, working The staff monitored the growth of vegetables through a unique “growth management system” in Chiba Prefecture. It takes about 20 days for vegetables to start planting and seedling. On this basis, it can be harvested in more than ten days.

A plant factory greenhouse that requires 10 people to manage, can harvest 1 million vegetables a year and sell 100 million yen (about 5.87 million yuan). The plant factory also has a visitor room with a number of small plant factories for home and university teaching, the size of which is comparable to a refrigerator-freezer, and the ability to connect with others via a web app.

In recent years, plant factories have become a popular target for global agricultural investment. One of the reasons for the increase in investment, according to the relevant personnel, is the large-scale use of LED lights in plant factories. In the past, the cost of plant factories accounted for about 25% of electricity costs. After the use of LED grow lights, the electricity bills dropped significantly, which reduced investment costs. It is understood that artificial light type plant factories mainly produce various vegetables, and researchers are concerned about higher value-added medicines such as marijuana.

The Foresight of Japanese Agriculture

At the beginning of 2017, some media reported that some factories in Japan were poorly managed, 70% of the profits were difficult, and big companies such as Toshiba had divested. Previously, many Japanese farmers had started to plant plants at a subsidy of 70%. However, due to the lack of relevant technology, these plant factories have successively closed down after exhausting government subsidies. In this regard, experts say that the current truly profitable plant factories in Japan account for about 30%. But he believes that it is not surprising that 70% of plant factories have deficits. "The negatives of the media on new things should not be over-emphasized. 50 years ago, no one agreed to grow vegetables in greenhouses. Now 80% of tomatoes and 90% of strawberries in Japan are Planted in the greenhouse."

In addition, the lack of funds is also a major bottleneck restricting the development of Japanese agriculture. Due to insufficient investment, Japan and South Korea are at a dangerous state in the development of plant factories. Sun Zhengyi, the richest man in Japan and the CEO of Softbank Group of Japan, has invested in an American plant factory.

Although Japanese farmers have the patience and patience of “embroidery”, Japanese agricultural enterprises have long been a phenomenon of “single fight alone” and are also factors that restrict their agricultural development. When introducing the original intention of the establishment of the autumn color farm, Ito said that in the past, Japan’s agriculture was “pointing to one-way”, “research is research, production is produced, and circulation is circulating”. Taking the Japanese agricultural breeding model as an example, Ito Shengmin tells us that there are only two large-scale nursery companies in Japan. The quality of seeds cultivated by many small-scale nursery workshops is not bad, but because the production chain is not opened, the added value is low.

Japanese-style profit model

In the development of world agriculture, at least 85% can not achieve secondary profits. For example, the farmer planted 100 acres of wheat, and the core income came from selling wheat. Once you encounter slow sales, you have to lose money. But in this respect, Japan's experience is worth learning. One example is Japan, which has found a new profit model for ordinary rice. Japanese rice field painting is a direction worth learning.

Tianshan Village is the originator of Japanese rice field painting. Inspired by the crop circle, in order to revitalize the local economy and develop tourism resources, in 1993 the villagers began to make rice fields. The rice field paintings have different themes every year. They are very extensive in Japan and abroad.

Today, the number of visitors to the Tianshan Village has exceeded 200,000. Even some big companies have come to the door, hoping to use the rice fields of farmers to make "advertisement ads" for them. The rice field art of the rice paddy growing season attracts a large number of tourists; after the rice harvest in autumn and winter, the rice straw is turned into a work of art, which also realizes the value of rice fields. Japan's rice field paintings have activated the farming industry. In addition to income from agricultural products sales, farmers' income can also develop creative agriculture to increase income.

In fact, from the above process of agricultural development in Japan, we can easily find that the development of science and technology and new technology has impacted the development of traditional agriculture. How to make better use of contemporary technology and creative ideas has become the focus of modern agricultural development.

For the plant factories,you can find more information from the following articles:

《The Analysis Of Vertical Farm Development Prospect》

《How To Build A Successful Plant Factory》

《How To Grow The Plants With LED Grow Lights》

Computer Farming During The Day, Robots On Duty At Night

Located in Fujita's "Autumn" smart farm in Putian City, Shizuoka Prefecture, Japan, the Autumn Color Farm covers an area of 85,000 square meters and has 12 football fields. There are many vegetable greenhouses up to 6 meters in the park, and the exterior is all glass. The steel frame structure at the top of the greenhouse is also very small, the farm official said, this is to ensure a larger area of light.

Before entering the greenhouse where one of the colorful peppers is grown, the staff wears a plastic jacket, rubber gloves and disinfection of the soles and hands. It is strictly forbidden to touch the plants by hand to ensure that the environment is as sterile as possible.

Rows of plant plants are cultivated in dedicated artificially cultivated soil, and water, nutrient solution, and carbon dioxide are connected through the pipeline from the bottom. The branches of the colored peppers continue to grow along the hanging steel wire, and the staff needs a special lift truck to enter the rows of plants for picking. The humidity and nutrient supply in the greenhouse are controlled by computers.

Qiu Cai Farm Specialist Ito Shengmin said that Qiu Cai Farm was jointly established by a well-known Japanese IT company Fujitsu and an agricultural finance company and a local seed research and development company in Putian in 2016. At present, Qiu Cai Farm has initially realized the high degree of automation of environmental control and the visualization of operation management. The staff can observe the temperature, humidity, and daily light of the greenhouse in real time through multiple displays in the main building to realize remote operation and cloud data. Japanese typhoons are frequent. When a typhoon strikes, the staff can remotely control the skylights in the greenhouse.

In the greenhouse, there are self-propelled robots walking along the track at night, using LED growing Lights to provide additional light to the greenhouse, monitoring the plants with other equipment, and forming a photosynthesis color image for the staff to adjust the temperature and humidity.

"Plant Factory" Into Investment Hot

The so-called "plant factory" uses the computer to automatically control the environmental conditions such as temperature, humidity, light, carbon dioxide concentration and nutrient solution of plant growth, and realizes mass production of plants in a short period of time and a small space to realize crops. Efficient agricultural systems for continuous production. The concept of “plant factory” first appeared in Northern Europe, but it was first applied in Japan on a large scale. There are currently more than 400 artificial plant factories in the world, half of which are in Japan.

Located in a plant in Chiba Prefecture, in a two-story building surrounded by vegetable greenhouses in the National Chiba University campus, the 74-year-old director of the Japan Plant Factory Research Society, said in the tree plant, the plant is a closed environment, working The staff monitored the growth of vegetables through a unique “growth management system” in Chiba Prefecture. It takes about 20 days for vegetables to start planting and seedling. On this basis, it can be harvested in more than ten days.

A plant factory greenhouse that requires 10 people to manage, can harvest 1 million vegetables a year and sell 100 million yen (about 5.87 million yuan). The plant factory also has a visitor room with a number of small plant factories for home and university teaching, the size of which is comparable to a refrigerator-freezer, and the ability to connect with others via a web app.

In recent years, plant factories have become a popular target for global agricultural investment. One of the reasons for the increase in investment, according to the relevant personnel, is the large-scale use of LED lights in plant factories. In the past, the cost of plant factories accounted for about 25% of electricity costs. After the use of LED grow lights, the electricity bills dropped significantly, which reduced investment costs. It is understood that artificial light type plant factories mainly produce various vegetables, and researchers are concerned about higher value-added medicines such as marijuana.

The Foresight of Japanese Agriculture

At the beginning of 2017, some media reported that some factories in Japan were poorly managed, 70% of the profits were difficult, and big companies such as Toshiba had divested. Previously, many Japanese farmers had started to plant plants at a subsidy of 70%. However, due to the lack of relevant technology, these plant factories have successively closed down after exhausting government subsidies. In this regard, experts say that the current truly profitable plant factories in Japan account for about 30%. But he believes that it is not surprising that 70% of plant factories have deficits. "The negatives of the media on new things should not be over-emphasized. 50 years ago, no one agreed to grow vegetables in greenhouses. Now 80% of tomatoes and 90% of strawberries in Japan are Planted in the greenhouse."

In addition, the lack of funds is also a major bottleneck restricting the development of Japanese agriculture. Due to insufficient investment, Japan and South Korea are at a dangerous state in the development of plant factories. Sun Zhengyi, the richest man in Japan and the CEO of Softbank Group of Japan, has invested in an American plant factory.

Although Japanese farmers have the patience and patience of “embroidery”, Japanese agricultural enterprises have long been a phenomenon of “single fight alone” and are also factors that restrict their agricultural development. When introducing the original intention of the establishment of the autumn color farm, Ito said that in the past, Japan’s agriculture was “pointing to one-way”, “research is research, production is produced, and circulation is circulating”. Taking the Japanese agricultural breeding model as an example, Ito Shengmin tells us that there are only two large-scale nursery companies in Japan. The quality of seeds cultivated by many small-scale nursery workshops is not bad, but because the production chain is not opened, the added value is low.

Japanese-style profit model

In the development of world agriculture, at least 85% can not achieve secondary profits. For example, the farmer planted 100 acres of wheat, and the core income came from selling wheat. Once you encounter slow sales, you have to lose money. But in this respect, Japan's experience is worth learning. One example is Japan, which has found a new profit model for ordinary rice. Japanese rice field painting is a direction worth learning.

Tianshan Village is the originator of Japanese rice field painting. Inspired by the crop circle, in order to revitalize the local economy and develop tourism resources, in 1993 the villagers began to make rice fields. The rice field paintings have different themes every year. They are very extensive in Japan and abroad.

Today, the number of visitors to the Tianshan Village has exceeded 200,000. Even some big companies have come to the door, hoping to use the rice fields of farmers to make "advertisement ads" for them. The rice field art of the rice paddy growing season attracts a large number of tourists; after the rice harvest in autumn and winter, the rice straw is turned into a work of art, which also realizes the value of rice fields. Japan's rice field paintings have activated the farming industry. In addition to income from agricultural products sales, farmers' income can also develop creative agriculture to increase income.

In fact, from the above process of agricultural development in Japan, we can easily find that the development of science and technology and new technology has impacted the development of traditional agriculture. How to make better use of contemporary technology and creative ideas has become the focus of modern agricultural development.

For the plant factories,you can find more information from the following articles:

《The Analysis Of Vertical Farm Development Prospect》

《How To Build A Successful Plant Factory》

《How To Grow The Plants With LED Grow Lights》

2018年12月18日星期二

Why Does The LED Light Flicker?

Everyone in today's life is equipped with LED lights. When the led lights are turned on, they will emit various colors of light. It is very beautiful. Many people are loyal to led lights. In the process of using LEDs, there is often a flash. In the case of flashing, what is the reason for this? Next, we will explore the causes and solutions of the LED flashing.

The Reason Why The LED Light Flashes

1, LED lamp beads and LED drive power supply do not match, normal single foot 1W lamp beads withstand current: 280-300mA, voltage: 3.0-3.4V, if the lamp bead chip is not enough power will cause the light source strobe phenomenon, When the current is too high, the lamp bead can't withstand and it will be turned on and off. In serious cases, the gold wire or copper wire built in the lamp bead will be blown, resulting in the lamp bead not shining.

2. It may be that the drive power supply is broken. Just replace it with another good drive power supply and it will not flash.

3. If the drive has over-temperature protection function, and the thermal performance of the material of the luminaire cannot meet the requirements, the drive over-temperature protection will start to work, for example, the 20W floodlight cover is used to assemble the 30W luminaire. This is the case if the heat dissipation work is not done well.

4. If the outdoor lighting also has a strobe light, the light is in the water. The consequence is that it will not light up when it flashes. The lamp bead and the drive are broken. If the drive is waterproof, if it is good, it will just break the lamp bead and replace the light source.

LED Lamp Maintenance Inspection Steps Are as Follows:

1. Before turning on the LED, measure the voltage of the power supply and the current flowing through the LED.

2, then disassemble, check all the key parts: drive or power supply, LED lamp beads, and all the broken lamp beads are replaced.

3, to find out the cause of LED lamp bead damage, if the current is too large, immediately reduce the drive current, and at the same time check the drive for faults, choose to repair or replace.

LED Energy-Saving Lamp Fault Repair Skills

1. Commonly, the resonant capacitor C6 breakdown (short circuit) or withstand voltage drop (soft breakdown) should be replaced with high-quality polyester or CBB capacitor of the same capacity with a withstand voltage above 1kV.

2. The lamp filament is open. If the lamp is not seriously blackened, it can be used in emergency after connecting 0.047μF/400V polyester capacitor at both ends of the broken wire.

3.R1, R2 open circuit or variable value (generally R1 failure is more likely), replace with the same resistance value of 1/4W high-quality resistor.

4. The triode is open. If only one triode is found to be open, but one cannot be replaced, a pair of matching switches of the same type with a withstand voltage of 400V or more should be replaced. Otherwise, it is easy to roll the light or burn the tube again.

5.the lights flashing non-stop. If the lamp is not seriously black, check whether D5 or D6 has a virtual weld or open circuit. If the D5 or D6 soft breakdown or the filter capacitor C1 leaks and is bad, the light will flash continuously.

6.the lamp is difficult to light, sometimes touch the lamp with the hand can light up or light roll, this may be C3, C4 capacity is insufficient, no pairing.

7. If the filament has redness or luminescence after the single low-power energy-saving lamp is lit, it should also check whether D1~D4 have a soft breakdown, whether C1 is leaked, and whether there is a short circuit in the power supply part.

8. The core of the choke coil L and the oscillating transformer B is broken. If you change the core, you should pay attention to three points: (1) Use the magnetic core that meets the requirements. Otherwise, the inductance value of the choke coil may be greatly different, and the energy-saving lamp may be buried. (2) The magnetic gap should not be too small to avoid Magnetic saturation; (3) After the magnetic gap is padded with a suitable pad, it has adhered with an adhesive and wrapped with a high-temperature resistant flame retardant tape to prevent loosening. In addition, the same name of B cannot be wrong.

9. Overhaul the electronic ballast using the trigger tube. The bidirectional trigger diode should be inspected. This tube is generally DB3 type, and its bidirectional breakdown voltage is 32±4V.

If you are unfamiliar with LED lights or have safety hazards, contact your local electrician for inspection.

Regarding led lights, you may be interested in the following:

《5 Ways To Maintain LED Lights》

《3 Types of LED Lighting Problems And Solutions》

《How To Choose A High Quality LED Corn Lights》

The Reason Why The LED Light Flashes

1, LED lamp beads and LED drive power supply do not match, normal single foot 1W lamp beads withstand current: 280-300mA, voltage: 3.0-3.4V, if the lamp bead chip is not enough power will cause the light source strobe phenomenon, When the current is too high, the lamp bead can't withstand and it will be turned on and off. In serious cases, the gold wire or copper wire built in the lamp bead will be blown, resulting in the lamp bead not shining.

2. It may be that the drive power supply is broken. Just replace it with another good drive power supply and it will not flash.

3. If the drive has over-temperature protection function, and the thermal performance of the material of the luminaire cannot meet the requirements, the drive over-temperature protection will start to work, for example, the 20W floodlight cover is used to assemble the 30W luminaire. This is the case if the heat dissipation work is not done well.

4. If the outdoor lighting also has a strobe light, the light is in the water. The consequence is that it will not light up when it flashes. The lamp bead and the drive are broken. If the drive is waterproof, if it is good, it will just break the lamp bead and replace the light source.

LED Lamp Maintenance Inspection Steps Are as Follows:

1. Before turning on the LED, measure the voltage of the power supply and the current flowing through the LED.

2, then disassemble, check all the key parts: drive or power supply, LED lamp beads, and all the broken lamp beads are replaced.

3, to find out the cause of LED lamp bead damage, if the current is too large, immediately reduce the drive current, and at the same time check the drive for faults, choose to repair or replace.

LED Energy-Saving Lamp Fault Repair Skills

1. Commonly, the resonant capacitor C6 breakdown (short circuit) or withstand voltage drop (soft breakdown) should be replaced with high-quality polyester or CBB capacitor of the same capacity with a withstand voltage above 1kV.

2. The lamp filament is open. If the lamp is not seriously blackened, it can be used in emergency after connecting 0.047μF/400V polyester capacitor at both ends of the broken wire.

3.R1, R2 open circuit or variable value (generally R1 failure is more likely), replace with the same resistance value of 1/4W high-quality resistor.

4. The triode is open. If only one triode is found to be open, but one cannot be replaced, a pair of matching switches of the same type with a withstand voltage of 400V or more should be replaced. Otherwise, it is easy to roll the light or burn the tube again.

5.the lights flashing non-stop. If the lamp is not seriously black, check whether D5 or D6 has a virtual weld or open circuit. If the D5 or D6 soft breakdown or the filter capacitor C1 leaks and is bad, the light will flash continuously.

6.the lamp is difficult to light, sometimes touch the lamp with the hand can light up or light roll, this may be C3, C4 capacity is insufficient, no pairing.

7. If the filament has redness or luminescence after the single low-power energy-saving lamp is lit, it should also check whether D1~D4 have a soft breakdown, whether C1 is leaked, and whether there is a short circuit in the power supply part.

8. The core of the choke coil L and the oscillating transformer B is broken. If you change the core, you should pay attention to three points: (1) Use the magnetic core that meets the requirements. Otherwise, the inductance value of the choke coil may be greatly different, and the energy-saving lamp may be buried. (2) The magnetic gap should not be too small to avoid Magnetic saturation; (3) After the magnetic gap is padded with a suitable pad, it has adhered with an adhesive and wrapped with a high-temperature resistant flame retardant tape to prevent loosening. In addition, the same name of B cannot be wrong.

9. Overhaul the electronic ballast using the trigger tube. The bidirectional trigger diode should be inspected. This tube is generally DB3 type, and its bidirectional breakdown voltage is 32±4V.

If you are unfamiliar with LED lights or have safety hazards, contact your local electrician for inspection.

Regarding led lights, you may be interested in the following:

《5 Ways To Maintain LED Lights》

《3 Types of LED Lighting Problems And Solutions》

《How To Choose A High Quality LED Corn Lights》

2018年12月13日星期四

The Analysis of Vertical Farm Development Prospect

What is vertical agriculture?

Vertical agriculture is an urban agriculture, and crops are grown throughout the year, often in extremely controlled environments, such as indoors. In addition to growing crops, some have developed a way to farm fish in a self-sustaining system. The water from the plants is recycled into the aquarium, and the fish waste becomes the fertilizer of the plants. Plants and fish can then be harvested for food.

Vertical farms around the world are emerging

In recent years, plant factories and vertical farms have gradually emerged everywhere, and the construction methods are varied, and vegetables can be grown on the ground, underground, in the air, at sea, and in containers.

The tunnel built LED vertical farm

According to reports, an indoor agricultural company called NextOn leased a closed tunnel in South Korea and transformed it into a smart farm by using vertical stacking, using hydroponics and LED lighting to grow crops. According to the company, this is the world's first indoor vertical farm built in a tunnel and the largest vertical farm in Korea, covering an area of 2,300 square meters.

A vertical farm in Scotland reduces energy consumption by 50% with LED lighting

Recently, in Scotland, IGS launched Scotland's first vertical farm and claimed it is the world's most advanced indoor farm with its patented power and communication technology.

It is reported that IGS's vertical farm is located at the James Hutton Institute, and researchers work with the IGS team to explore the impact of different growing lights on crop yield and quality.

According to IGS, vertical farms can be monitored through a single platform. This solution will help reduce energy consumption by 50% compared to other indoor growing environments.

Vacant industrial land change indoor vertical farm

In Las Vegas, USA, a company called Oasis Biotech turned a vacant industrial site into one of the largest indoor vertical farms in the United States. Vertical farms have been serving restaurants in Las Vegas since opening last month. Due to the installation of LED lighting systems and a controlled indoor environment, the farm can grow fresh vegetables throughout the year.

The ultimate goal of vertical agriculture is to reduce water waste, eliminate pesticide use and shorten food miles, and reduce food waste by 90% by locally growing and growing fresh vegetables on demand.

Germany grows fruits and vegetables directly in the supermarket

The Metro chain supermarket in Berlin, Germany, cooperates with Infarm to promote the indoor vertical farm program, planting fruits and vegetables directly in the supermarket and selling them at the same time, so that customers can easily and personally harvest the fresh ingredients to be purchased.

Infarm is committed to growing food in a variety of impossible places, using old containers to create stackable modular planting boxes, via an internet-controlled irrigation and nutrient supply system, simulating sunlight. In order to help plant the LED lighting for photosynthesis, and to install a variety of sensing equipment to monitor the situation, consumers can also know the growth process of the food in real time through the network.

In the supermarket walkway cover vertical farm, it only takes up a few square meters of small space in the supermarket and can extend upwards and expands. The biggest benefit is that the supermarket infrastructure is complete, no need for any additional construction or adjustments, just install the system and start working. It is beneficial to consumers with many advantages such as reducing the transportation, storage and preservation costs of food materials, and is favored by consumers.

Dubai will build the world's largest vertical farm

According to media reports, Dubai is about to build the world's largest vertical farm. After completion, it will occupy 18.11 acres, but the output is equivalent to 5463.2 acres of farmland. Under full production, the plant produces 2,700 kilograms of high quality, herbicide-free, and pesticide-free green leafy vegetables per day, and water consumption is 99% less than outdoor planting.

There are about 26 vertical farms in Singapore

According to the Singapore Straits Times, strawberries grown in vertical farms in Singapore are now available in some supermarkets for 12 Singapore dollars per basket. Strawberries are warm and cool, while Singapore is tropical and not suitable for growing strawberries. It is often necessary to import strawberries from abroad. Today, with the high-tech of vertical farms, Singapore's strawberries can also be produced and sold. Although this price is not cheaper than imported strawberries, the farmer produces high-quality fruits and vegetables and sustainable agriculture. It can save long-distance transportation by selling and selling in Singapore, which not only ensures the freshness of fruits and vegetables but also is more environmentally friendly, even on price. There is no big advantage and it is more competitive than imported strawberries.

Vertical agriculture is an urban agriculture, and crops are grown throughout the year, often in extremely controlled environments, such as indoors. In addition to growing crops, some have developed a way to farm fish in a self-sustaining system. The water from the plants is recycled into the aquarium, and the fish waste becomes the fertilizer of the plants. Plants and fish can then be harvested for food.

Vertical farms around the world are emerging

In recent years, plant factories and vertical farms have gradually emerged everywhere, and the construction methods are varied, and vegetables can be grown on the ground, underground, in the air, at sea, and in containers.

The tunnel built LED vertical farm

According to reports, an indoor agricultural company called NextOn leased a closed tunnel in South Korea and transformed it into a smart farm by using vertical stacking, using hydroponics and LED lighting to grow crops. According to the company, this is the world's first indoor vertical farm built in a tunnel and the largest vertical farm in Korea, covering an area of 2,300 square meters.

A vertical farm in Scotland reduces energy consumption by 50% with LED lighting

Recently, in Scotland, IGS launched Scotland's first vertical farm and claimed it is the world's most advanced indoor farm with its patented power and communication technology.

It is reported that IGS's vertical farm is located at the James Hutton Institute, and researchers work with the IGS team to explore the impact of different growing lights on crop yield and quality.

According to IGS, vertical farms can be monitored through a single platform. This solution will help reduce energy consumption by 50% compared to other indoor growing environments.

Vacant industrial land change indoor vertical farm

In Las Vegas, USA, a company called Oasis Biotech turned a vacant industrial site into one of the largest indoor vertical farms in the United States. Vertical farms have been serving restaurants in Las Vegas since opening last month. Due to the installation of LED lighting systems and a controlled indoor environment, the farm can grow fresh vegetables throughout the year.

The ultimate goal of vertical agriculture is to reduce water waste, eliminate pesticide use and shorten food miles, and reduce food waste by 90% by locally growing and growing fresh vegetables on demand.

Germany grows fruits and vegetables directly in the supermarket