The rapid growth of population and the trend of urbanization are expected to promote and promote the development and growth of the vertical farm industry. Vertical farms are thought to solve some of the problems of food production, but whether it can be a sustainable solution for food production, experts believe that there are still challenges. According to a UN survey, the global population will grow from the current 7.3 billion people to 8.5 billion in 2030 and 9.7 billion in 2050. FAO estimates that in order to meet and feed the population of 2050, food production will increase by 70% from 2007 levels, global cereal production must increase from 2.1 billion tons to 3 billion tons by 2050, and meat needs to be doubled to 470 million tons.

According to a UN survey, the global population will grow from the current 7.3 billion people to 8.5 billion in 2030 and 9.7 billion in 2050. FAO estimates that in order to meet and feed the population of 2050, food production will increase by 70% from 2007 levels, global cereal production must increase from 2.1 billion tons to 3 billion tons by 2050, and meat needs to be doubled to 470 million tons.

How to solve the problem of demand due to the increase in population? Many people point out that adjusting and adding more land as agricultural production is not always possible in some countries. For example, the United Kingdom has used 72% of the land to produce the most agricultural products, but still needs to import food. The United Kingdom has also tried to use other methods for farming, such as the use of air defense tunnels left over from World War II combined with full-spectrum LED grow lights for greenhouse cultivation. The sponsors also plan to expand the planting range in 2019.《Does The Full Spectrum Grow Lights Cause Harm To Humans?》

《Is The LED Grow Lights Really Useful?》

《Can Be Eaten The Vegetables Which Grows With The LED Grow Lights》On the other hand, water use is also a barrier to food production. About 70% of OECD's water use is for farms. Climate change has also exacerbated production problems. Urbanization also requires food production systems to feed the population of urban populations with less labor, limited land and water resources in the countryside. These issues are driving the development of vertical farms and high-quality plant lights. The low-use nature of vertical farms will provide opportunities for agricultural production to enter the city, closer to urban consumers, reduce the distance from farms to consumers, and shorten the entire supply chain. Urban consumers will be more interested in Food sources and easier access to fresh nutritious production. In the past, urban people did not have easy access to healthy fresh food. Vertical farms could be built directly in the kitchen or in their backyard, using the light provided by LED growing lights, which would be the most important message conveyed by vertical farm development.

The low-use nature of vertical farms will provide opportunities for agricultural production to enter the city, closer to urban consumers, reduce the distance from farms to consumers, and shorten the entire supply chain. Urban consumers will be more interested in Food sources and easier access to fresh nutritious production. In the past, urban people did not have easy access to healthy fresh food. Vertical farms could be built directly in the kitchen or in their backyard, using the light provided by LED growing lights, which would be the most important message conveyed by vertical farm development.

In addition, the adoption of a vertical farm model will have a wide-ranging impact on traditional agricultural supply chains, and the use of traditional agricultural drugs such as synthetic fertilizers, pesticides, and herbicides will be significantly reduced. On the other hand, the demand for HVAC systems and control systems will increase to maintain optimal conditions for climate river management, special LED lighting for simulating sunlight, and other equipment to set up indoors or Outdoor architecture.

For vertical farm development, the Internet of Things (IoT) technology will also play an important role in recording plant growth data, crop harvesting will be traceable, and monitored elsewhere by computer or mobile phone.

In fact, vertical farms can produce more food with less land and water, and away from harmful chemical fertilizers and pesticides. However, shelves stacked indoors require more energy than traditional agriculture. Even if there are windows in the room, artificial light is usually required for other restrictions. Climate control systems provide the best growth environment, but they are also quite energy intensive.

According to the statistics of the British Ministry of Agriculture, lettuce is grown in the greenhouse, and it is estimated that about 250 kWh (kWh) of energy per square meter of planting area per year. According to the relevant collaborative research of the German DLR Research Center, the vertical farms in the same size planting area require an amazing energy consumption of 3,500 kWh per year. Therefore, how to improve acceptable energy use will be an important issue for the future development of vertical farm technology.

However, we believe that with the continuous upgrading of technology, the development of vertical farms will gradually meet the human needs for food, and the development of LED plant lights will also allow agricultural production to enter the city so that humans can enjoy greener foods that are healthier and more environmentally friendly.《How To Build A Successful Plant Factory?》

《The Analysis of Vertical Farm Development Prospect》

It is a very common phenomenon that LED lights are easily darkened after use. Summarizing the reasons for the darkening of LED lights is nothing more than the following three points.

Drive Damage

LED lamp beads are required to work at DC low voltage (below 20V), but our usual mains supply is AC high voltage (AC 220V). To turn the mains into the electricity needed for the lamp, you need a device called "LED constant current drive power."

In fact, as long as the parameters of the driver match the lamp bead, the power supply can be continuously used and used normally. The internals of the drive is complicated, and any device (such as capacitors, rectifiers, etc.) may cause a change in the output voltage, which may cause the lamp to become dark. Drive damage is one of the most common faults in LED luminaires and can usually be resolved after replacing the drive.

Drive damage is one of the most common faults in LED luminaires and can usually be resolved after replacing the drive.

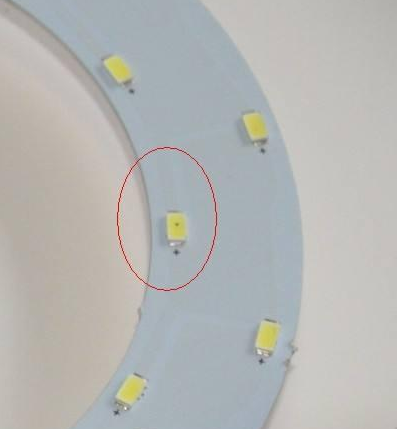

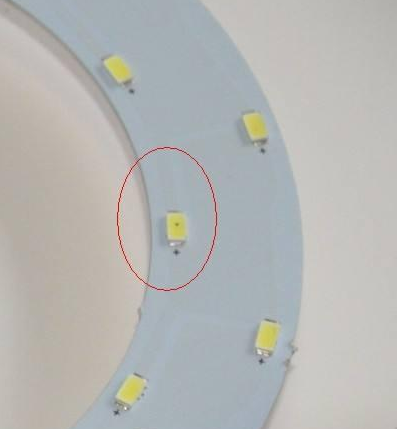

LED Lamp Bead Burned

The LED itself is composed of one lamp bead. If one or a part of it is not lit, it will inevitably make the whole fixture dark. Lamp beads are generally connected in series and then in parallel - so if a lamp bead burns, it may cause a batch of lamp beads to be off.

After burning, the surface of the lamp bead has obvious black spots. Find it, use a wire to connect it to the back of the lamp, short-circuit it, or replace it with a new lamp bead. It’s a coincidence that the LED burns one at a time. If it burns frequently, consider the drive problem - another manifestation of drive failure is burning the lamp bead.

It’s a coincidence that the LED burns one at a time. If it burns frequently, consider the drive problem - another manifestation of drive failure is burning the lamp bead.

LED Light Decay

The so-called light decay is that the brightness of the illuminant is getting lower and lower - this situation is more obvious on incandescent and fluorescent lamps.

LED lights cannot avoid light decay, but its light decay rate is relatively slow, it is difficult to see changes with the naked eye. However, it does not rule out inferior LEDs, or inferior light beads, or due to objective factors such as poor heat dissipation, resulting in faster-LED light decay.

Therefore, when we choose the LED light, we must choose the quality and quality assurance business to ensure that the LED lamp has a longer service life.《5 Ways To Maintain LED Lights》

《How To Choose A High Quality LED Corn Lights》

《How To Choose A High Quality LED Bulb Lights》

Plant Factory And Its Social Significance Plant Factory, in a broad sense, refers to a system of plant cultivation systems that fully or partially controls the environmental conditions required for plant growth to grow completely or partially unaffected by the natural environment. Its main feature is that the planting space is closed, and the artificial light completely replaces the sunlight. The production factors (carbon dioxide, oxygen, temperature, humidity, fertilizer nutrients, illumination, etc.) are fully and accurately controlled. The whole year is continuously cultivated, and the production cycle is fast. Customized by a plan, etc. The whole process is carried out on the factory production line, which makes the product more refined, homogenized and productive.

Plant Factory, in a broad sense, refers to a system of plant cultivation systems that fully or partially controls the environmental conditions required for plant growth to grow completely or partially unaffected by the natural environment. Its main feature is that the planting space is closed, and the artificial light completely replaces the sunlight. The production factors (carbon dioxide, oxygen, temperature, humidity, fertilizer nutrients, illumination, etc.) are fully and accurately controlled. The whole year is continuously cultivated, and the production cycle is fast. Customized by a plan, etc. The whole process is carried out on the factory production line, which makes the product more refined, homogenized and productive.

According to statistics, the global population will exceed 9 billion by 2050. The global issues of the 21st century are four aspects of food, resources, environment, and quality of life. Deterioration of the natural environment includes soil compaction caused by human factors, soil salinization, heavy metal pollution, severe haze, and desertification. Plant factories can solve the supply of vegetables in extreme environments. For example, soldiers working in desert conditions, workers working on offshore platforms need to regularly distribute vegetables and other foods, and only vegetables that are resistant to storage, less Fresh leafy vegetables. In addition, the world's major powers are scrambling to study various technical means of exploring space. Plant factories are an important research topic.

Plant factories can solve the supply of vegetables in extreme environments. For example, soldiers working in desert conditions, workers working on offshore platforms need to regularly distribute vegetables and other foods, and only vegetables that are resistant to storage, less Fresh leafy vegetables. In addition, the world's major powers are scrambling to study various technical means of exploring space. Plant factories are an important research topic.

The Development Direction of The Combination of Plant Factories And Lighting Industry

The light sources used in the development of plant factories mainly include high-pressure sodium lamps, fluorescent lamps, metal halide lamps, incandescent lamps, etc. The outstanding disadvantages of these light sources are high energy consumption, high operating costs, and energy consumption costs accounting for 50% of the total operating costs. -60%. In recent years, the LED light source developed not only emits monochromatic light with narrow light waves, but also can arbitrarily combine light sources according to plant needs, and the LED is a cold light source with low heat generation characteristics, which can illuminate plants at close range and improve space utilization. Providing a reasonable light environment for plant growth, it is very suitable for the cultivation of plant plants in multiple layers.

Analysis of The Needs And Ppplication Characteristics of Plant Lighting Equipment in Plant Factories:

The basic requirements for the application of LED light source in plant factories are mainly reflected in three aspects, namely spectral performance - both to ensure the photosynthetic quality of plant photosynthesis, and to reduce the invalid spectrum and energy consumption as much as possible; luminous efficiency-- The amount of photosynthetically active radiation emitted is relatively high compared to the power consumption; the service life - long use time, low light decay, and relatively low price.

There are three main factors affecting the growth of crops grown in plant factories by LED light sources:

1.Light intensity - the intensity of light. It will not only affect the photosynthesis intensity but also change the shape of the crop, such as flowering stage, internode length, stem thickness, and leaf size thickness;

2.The photo-spectral distribution has an important influence on plant photosynthesis and morphogenesis. The plants on the earth are constantly adapting to solar radiation during long-term evolution, and different species have different light-selective absorption characteristics.

3.Photoperiod-photoperiod characteristics are closely related to the number of illumination hours. Different crops need a certain number of illumination hours to complete the photoperiod, and the opposite can also inhibit the flowering and fruiting of the crop by changing the illumination time.

The impact of a LED light source on the construction and use cost of plant factory. At present, the cost of the LED light source in plant construction accounts for 20%-50% of the construction cost, and the compression space is large; the installation efficiency, maintenance replacement frequency, power saving ratio, Attenuation speed, etc. will affect the actual use cost.

Future Development of Plants Combined With Plant Lighting Technology:

The cost performance of LED has been significantly improved in the past few years. Therefore, the industry of LED-based artificial light-type plant factories has also developed rapidly in recent years. It can be convinced and predicted that LEDs are based on LEDs with increasing cost performance. The artificial light plant factory will have a broader development space. The rapid rise of plant factories has also prompted the plant lighting industry to move forward in a favorable direction of research and development, standardization, and close cooperation between industries. In order to promote the efficient and healthy development of LED artificial light plant factories, the following problems need to be solved:

In order to promote the efficient and healthy development of LED artificial light plant factories, the following problems need to be solved:

1.In-depth study of the effects of artificial light sources on plant growth in plant factories. The complexity of plant photobiology research has made the mechanism of photobiology unclear so far, especially in the field of molecular biology. First of all, there are many kinds of plants and varieties, and photobiological needs are very complicated. Secondly, the wavelength of plant effect light is complex, involving many typical bands, and the individual effects and complex effects require long-term research. Finally, the most complicated is plant development. The output and quality indicators are diverse, the light control is difficult, and the single-index and composite indicators are complex. This requires close cooperation between the two industries to promote the solution.

2.Formulation and implementation of relevant standards for lighting fixtures for plant factories. Compared with lighting fixtures for homes, shopping malls, etc., LED agricultural use, especially for plant-specific lighting fixtures, still has product clutter, irregular production design, lack of uniform product standards and quality management issues. In addition to the lack of scientific uniform specifications in terms of light quality regulation and light intensity, there is a lack of design specifications for protection against electricity, water, and corrosion in high-humidity environments of plant factories. Some lamps have a short service life and potential safety hazards.

3.The improvement of technology research and development investment and intellectual property protection system. At present, there are many small and medium-sized enterprises producing low-end products in LED plant lighting fixtures, lacking independent intellectual property rights and systematic research, which makes LED plant lighting products uneven, industrialization and standardization are low, and lack of market competitiveness.

High-end facility agriculture is the development trend of modern agricultural planting, and plant factories are the typical representative of this new concept and technical system. It can realize the high-efficiency agricultural system for continuous crop production through high-precision environmental control in the facility. It is the automatic control of the environmental conditions of plant growth by using a computer. It is a subversion of traditional agriculture, making plants grow free or rarely subject to natural conditions. The labor-saving production mode that is restricted is the advanced stage of agricultural development.

In the next three to five years, more industrial resources will enter, more capital will enter, and with the introduction of government support policies, the development of plant factories will enter a period of vigorous development. The development of plant factories has benefited from the good early stage of the LED industry, and the LED plant lighting or agricultural lighting field that has been or has been deployed by various LED companies. It is foreseeable that the cost of plant lighting is reduced and the professionalism is improved. As well as the continuous professional development and strategic cooperation of other related upstream industries, the plant factory will flourish, benefiting the general trend of consumption upgrading, and can solve part of the shortage of energy and cultivated land.XinJia is also constantly striving and innovating to provide customers with more high-quality LED grow lights.

Want to know more about plant factories?Browse the following articles:《How To Build A Succuessful Plant Factory?》

《LED Plant Factory-A New Dirextion For The Development of Smart Agriculture》

With the promotion of the legalization of marijuana, more and more people choose to buy seeds and LED grow lights to grow marijuana. As we all know, the cultivation of cannabis is not as simple as we think: temperature, climate, soil, water seal, light and other factors are essential for the growth of cannabis.

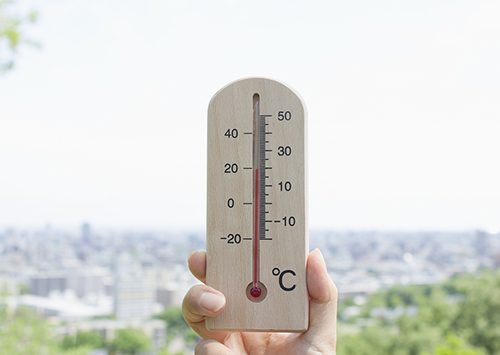

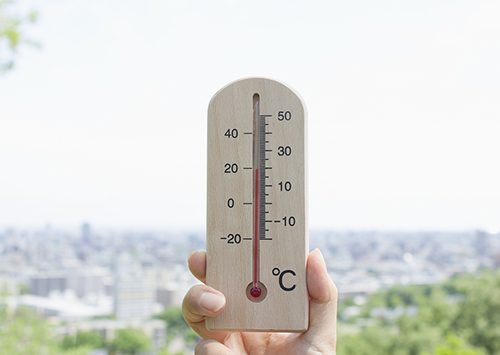

In fact, cannabis has different temperature requirements depending on the type of variety. Generally, from planting to maturity, the accumulated temperature required is 1900-2000. When the seeds are mature, the accumulated temperature is 2700-3000. For early maturing varieties, the accumulated temperature of 1600-1700. The process can be matured. Cannabis seeds can germinate when the soil temperature is above 1 °C, but it is necessary to sow when the soil temperature is above 8-10 °C. The optimum temperature for cannabis seed germination is 25-35 ° C. When the temperature is high, the germination is fast and uniform, and the highest temperature is not more than 45 ° C. Excessive temperature is easy to burn the seeds. Cannabis seedlings can withstand short-term low temperatures of -5 ° C, but this can seriously affect their growth process. The most suitable growth temperature: seedling stage is 10-15 °C; rapid growth period is 18-30 °C, 19-25 °C is the most suitable; flowering to seed maturity is 18-20 °C, flowering period meets -1 °C low temperature, then The flower is damaged, and the flower is dead below -2 °C, especially the male flower.

Cannabis seedlings can withstand short-term low temperatures of -5 ° C, but this can seriously affect their growth process. The most suitable growth temperature: seedling stage is 10-15 °C; rapid growth period is 18-30 °C, 19-25 °C is the most suitable; flowering to seed maturity is 18-20 °C, flowering period meets -1 °C low temperature, then The flower is damaged, and the flower is dead below -2 °C, especially the male flower.

Seeds can withstand 3-5 ° C low temperature and lower temperature within 10-15 days after germination; at -5 low temperature, its growth will be delayed. However, if sufficient water and nutrients are available, the low temperature at the seedling stage will have little effect on future development and yield.

Cannabis is not resistant to low temperatures during flowering, and it is prone to death during the flowering period, and it is easy to die. During the growth period, the average temperature around day and night has a great influence on the growth of cannabis, especially from the bud to the end of flowering, the growth of stems is the fastest, and the dry matter is greatly increased; during this period, the best temperature should be maintained at 16 (evening)-25 °C (daytime) or so. With the use of LED plant lights, indoor cannabis cultivation can better control the temperature required for cannabis by hand. Regardless of the planting method, we should be careful and caring for the cannabis in planting.

With the use of LED plant lights, indoor cannabis cultivation can better control the temperature required for cannabis by hand. Regardless of the planting method, we should be careful and caring for the cannabis in planting.